The weekly litigation news digest is live. Subscribe now

Coated Steel Strips, Methods Of Making The Same, Methods Of Using The Same, Stamping Blanks Prepared From The Same, Stamped Products Prepared From The Same, And Articles Of Manufacture Which Contain Such A Stamped Product - EP2086755

The patent EP2086755 was granted to Arcelormittal on Nov 29, 2017. The application was filed on Oct 30, 2006 under application number EP06842403A. The patent is currently recorded with a legal status of "Granted And Under Opposition".

EP2086755

- Application Number

- EP06842403A

- Filing Date

- Oct 30, 2006

- Status

- Granted And Under Opposition

- Oct 27, 2017

- Publication Date

- Nov 29, 2017

- External Links

- Slate, Register, Google Patents

Patent Summary

Coated steel sheets for hot stamping, comprising a steel substrate coated on at least one side with a uniform aluminum or aluminum alloy coating having a thickness between 20 and 33 micrometers, wherein the coating undergoes intermetallic alloying with the steel substrate during heating, and the resulting coated steel exhibits improved weldability and resistance to roller fouling in hot stamping processes.

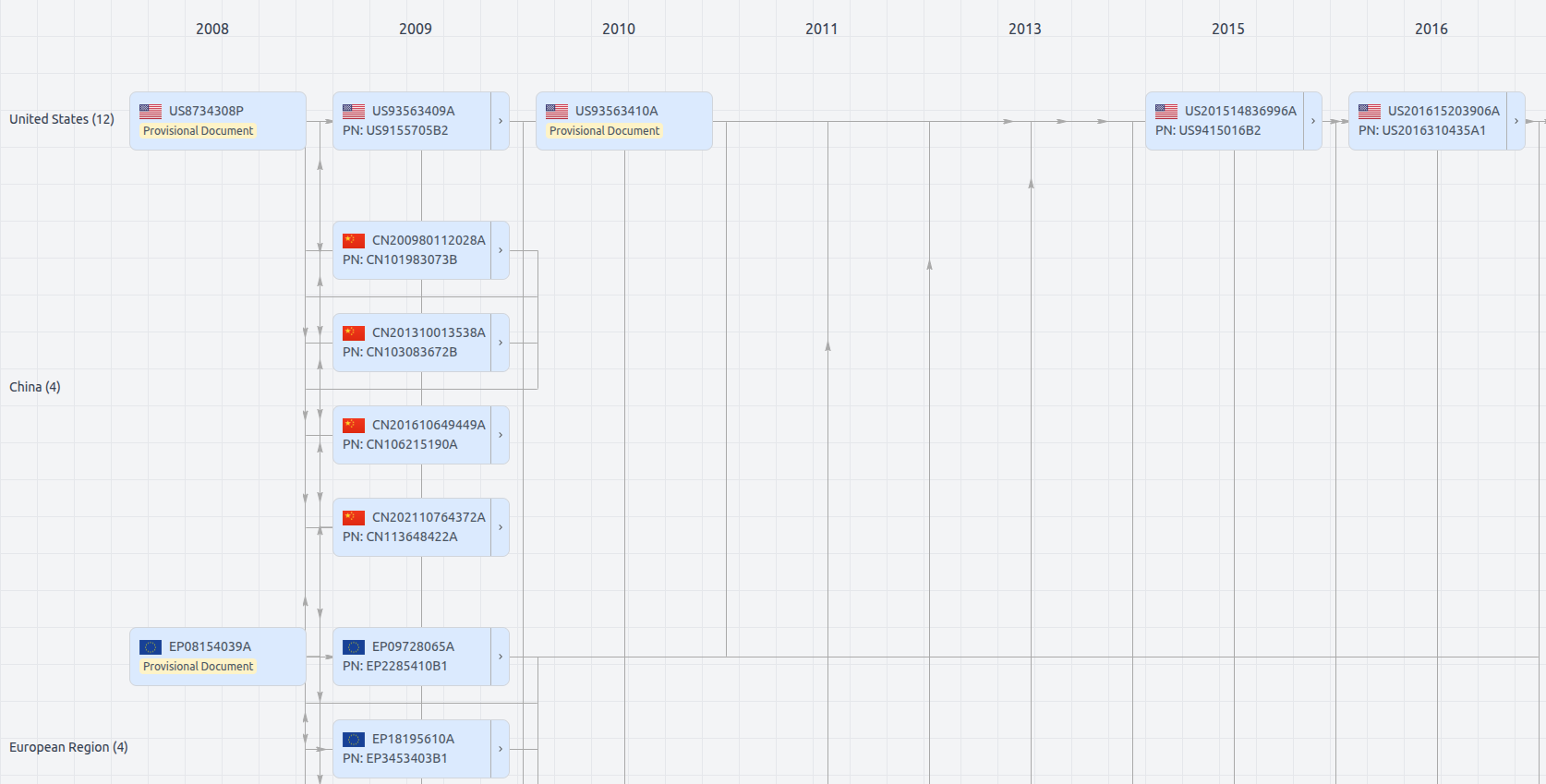

Patent Family

Patent Oppositions (5)

Patent oppositions filed by competitors challenge the validity of a granted patent. These oppositions are typically based on claims of prior art, lack of novelty, or non-obviousness. They are a key part of the process for determining a patent's strength and enforceability.

| Company | Opposition Date | Representative | Opposition Status |

|---|---|---|---|

| MUHR UND BENDER | Aug 29, 2018 | NEUMANN MULLER OBERWALLENEY PATENTANWALTE PARTG MBB | ADMISSIBLE |

| THYSSENKRUPP STEEL EUROPE | Aug 29, 2018 | EISENFUHR SPEISER | ADMISSIBLE |

| VOLKSWAGEN | Aug 29, 2018 | LIEBL | ADMISSIBLE |

| SALZGITTER FLACHSTAHL | Aug 28, 2018 | MOSER GOTZE & PARTNER PATENTANWALTE MBB | ADMISSIBLE |

| TATA STEEL IJMUIDEN | Aug 28, 2018 | GROUP SERVICES | ADMISSIBLE |

Patent Citations (16) New

Patent citations refer to prior patents cited during different phases such as opposition or international search.

| Citation Phase | Publication Number |

|---|---|

| INTERNATIONAL-SEARCH-REPORT | EP0356783 |

| INTERNATIONAL-SEARCH-REPORT | EP1013785 |

| INTERNATIONAL-SEARCH-REPORT | EP1336666 |

| INTERNATIONAL-SEARCH-REPORT | FR2720079 |

| INTERNATIONAL-SEARCH-REPORT | FR2758571 |

| INTERNATIONAL-SEARCH-REPORT | US6296805 |

| INTERNATIONAL-SEARCH-REPORT | WO2006097593 |

| OPPOSITION | DE102004007071 |

| OPPOSITION | EP1013785 |

| OPPOSITION | EP1380666 |

| OPPOSITION | EP2242863 |

| OPPOSITION | FR2833504 |

| OPPOSITION | US2001042393 |

| OPPOSITION | US6296805 |

| OPPOSITION | WO2005078144 |

| OPPOSITION | WO2008053273 |

Dossier Documents

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

Oct 30, 2025

Oct 30, 2025

Oct 30, 2025

Oct 30, 2025

Oct 30, 2025

Oct 30, 2025

Oct 17, 2025

Oct 17, 2025

Oct 17, 2025

Oct 17, 2025

Oct 17, 2025

Aug 25, 2025

Aug 25, 2025

Aug 25, 2025

Aug 25, 2025

Aug 25, 2025

Aug 25, 2025

Aug 25, 2025

Aug 20, 2025

Jul 30, 2025

Jul 30, 2025

Jul 30, 2025

Jul 30, 2025

Jul 30, 2025

Jul 30, 2025

Jul 30, 2025

Jul 30, 2025

Jul 30, 2025

Jul 30, 2025

Jul 30, 2025

Jul 30, 2025

Jul 30, 2025

Jul 25, 2025

Jun 30, 2025

Jun 25, 2025

Jun 11, 2025

Jun 11, 2025

Jun 11, 2025

Jun 11, 2025

Jun 11, 2025

Jun 5, 2025

(Electronic) Receipt

Appeal

Jun 5, 2025

Jun 5, 2025

May 12, 2025

May 12, 2025

May 12, 2025

May 12, 2025

May 12, 2025

May 7, 2025

(Electronic) Receipt

Appeal

May 7, 2025

May 7, 2025

Feb 18, 2025

Feb 18, 2025

Feb 17, 2025

Feb 13, 2025

Feb 12, 2025

Feb 11, 2025

(Electronic) Receipt

Appeal

Feb 11, 2025

Feb 11, 2025

Feb 11, 2025

Feb 11, 2025

Jan 31, 2025

Jan 31, 2025

Jan 31, 2025

Jan 31, 2025

Jan 31, 2025

Jan 28, 2025

(Electronic) Receipt

Appeal

Jan 28, 2025

Jan 28, 2025

Dec 9, 2024

Dec 6, 2024

Dec 6, 2024

Dec 5, 2024

Dec 5, 2024

Dec 5, 2024

Dec 5, 2024

Dec 5, 2024

Dec 3, 2024

Dec 3, 2024

Dec 3, 2024

Dec 3, 2024

Dec 3, 2024

Dec 3, 2024

Nov 29, 2024

(Electronic) Receipt

Appeal

Nov 29, 2024

Nov 29, 2024

Nov 28, 2024

(Electronic) Receipt

Appeal

Nov 28, 2024

Nov 28, 2024

Notice of appeal

Appeal

Oct 1, 2024

Oct 1, 2024

Oct 1, 2024

Oct 1, 2024

Oct 1, 2024

Oct 1, 2024

Oct 1, 2024

Oct 1, 2024

Oct 1, 2024

Oct 1, 2024

Oct 1, 2024

Oct 1, 2024

Oct 1, 2024

Oct 1, 2024

Oct 1, 2024

Oct 1, 2024

Means of redress

OPPO

Jun 11, 2024

Jun 11, 2024

Jun 11, 2024

Jun 11, 2024

Jun 11, 2024

Jun 5, 2024

Jun 5, 2024

Jun 5, 2024

May 6, 2024

May 6, 2024

May 6, 2024

May 6, 2024

May 6, 2024

May 6, 2024

May 6, 2024

May 6, 2024

May 6, 2024

May 6, 2024

May 6, 2024

May 6, 2024

May 6, 2024

Dec 8, 2023

Dec 8, 2023

Dec 8, 2023

Dec 8, 2023

Dec 8, 2023

Dec 4, 2023

Dec 4, 2023

Dec 4, 2023

Oct 6, 2023

Oct 6, 2023

Oct 6, 2023

Oct 6, 2023

Oct 6, 2023

Oct 6, 2023

Oct 6, 2023

Oct 6, 2023

Oct 6, 2023

Oct 6, 2023

Oct 6, 2023

Oct 6, 2023

Oct 6, 2023

May 15, 2023

May 15, 2023

May 15, 2023

May 15, 2023

May 15, 2023

May 5, 2023

May 5, 2023

May 5, 2023

May 5, 2023

May 5, 2023

Feb 9, 2023

Feb 9, 2023

Feb 9, 2023

Feb 9, 2023

Feb 9, 2023

Feb 9, 2023

Feb 9, 2023

Feb 9, 2023

Feb 9, 2023

Feb 9, 2023

Feb 9, 2023

Feb 9, 2023

Feb 9, 2023

Oct 20, 2022

Advice of delivery

Appeal

Oct 19, 2022

Advice of delivery

Appeal

Oct 17, 2022

Oct 17, 2022

Oct 17, 2022

Oct 17, 2022

Oct 17, 2022

Oct 17, 2022

Oct 17, 2022

Aug 5, 2022

Refund of fees

Appeal

Aug 3, 2022

Aug 3, 2022

Aug 3, 2022

Aug 3, 2022

Aug 3, 2022

Aug 3, 2022

Aug 3, 2022

Jul 18, 2022

Jul 18, 2022

Jul 18, 2022

Jul 18, 2022

Jul 18, 2022

Jul 13, 2022

(Electronic) Receipt

Appeal

Jul 13, 2022

Jul 13, 2022

Jul 13, 2022

Jun 30, 2022

Jun 30, 2022

Jun 30, 2022

Jun 27, 2022

(Electronic) Receipt

Appeal

Jun 27, 2022

Jun 27, 2022

Jun 24, 2022

(Electronic) Receipt

Appeal

Jun 24, 2022

Jun 24, 2022

Jun 23, 2022

Advice of delivery

Appeal

Jun 22, 2022

Advice of delivery

Appeal

Jun 21, 2022

Jun 21, 2022

Jun 15, 2022

Jun 14, 2022

Jun 9, 2022

(Electronic) Receipt

Appeal

Jun 9, 2022

(Electronic) Receipt

Appeal

Jun 9, 2022

Jun 9, 2022

Jun 9, 2022

Jun 9, 2022

Jun 8, 2022

Jun 8, 2022

Jun 8, 2022

Jun 8, 2022

Jun 8, 2022

Jun 2, 2022

(Electronic) Receipt

Appeal

Jun 2, 2022

Jun 2, 2022

May 30, 2022

May 24, 2022

(Electronic) Receipt

Appeal

May 24, 2022

May 24, 2022

Apr 29, 2022

Apr 8, 2022

Apr 5, 2022

(Electronic) Receipt

Appeal

Apr 5, 2022

Apr 5, 2022

Apr 4, 2022

Apr 4, 2022

Apr 4, 2022

Apr 4, 2022

Apr 4, 2022

Mar 28, 2022

(Electronic) Receipt

Appeal

Mar 28, 2022

Mar 28, 2022

Mar 15, 2022

Mar 15, 2022

Mar 15, 2022

Mar 15, 2022

Mar 15, 2022

Mar 10, 2022

(Electronic) Receipt

Appeal

Mar 10, 2022

Mar 10, 2022

Feb 22, 2022

Feb 22, 2022

Feb 22, 2022

Feb 22, 2022

Feb 22, 2022

Feb 17, 2022

(Electronic) Receipt

Appeal

Feb 17, 2022

Feb 17, 2022

Oct 18, 2021

Advice of delivery

Appeal

Oct 18, 2021

Oct 18, 2021

Oct 18, 2021

Oct 18, 2021

Oct 18, 2021

Oct 12, 2021

(Electronic) Receipt

Appeal

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Claims

Appeal

Oct 12, 2021

Oct 12, 2021

Oct 11, 2021

Advice of delivery

Appeal

Oct 7, 2021

Oct 7, 2021

Oct 7, 2021

Oct 7, 2021

Oct 7, 2021

Oct 7, 2021

Oct 4, 2021

Jun 15, 2021

Jun 15, 2021

Jun 15, 2021

Jun 15, 2021

Jun 15, 2021

Jun 9, 2021

(Electronic) Receipt

Appeal

Jun 9, 2021

Jun 9, 2021

Reply to appeal

Appeal

Feb 11, 2021

Feb 8, 2021

Feb 8, 2021

Feb 8, 2021

Feb 8, 2021

Feb 4, 2021

Feb 3, 2021

(Electronic) Receipt

Appeal

Feb 3, 2021

Feb 3, 2021

Feb 3, 2021

Reply to appeal

Appeal

Feb 2, 2021

(Electronic) Receipt

Appeal

Feb 2, 2021

Feb 2, 2021

Reply to appeal

Appeal

Feb 1, 2021

(Electronic) Receipt

Appeal

Feb 1, 2021

Feb 1, 2021

Reply to appeal

Appeal

Jan 27, 2021

Jan 22, 2021

(Electronic) Receipt

Appeal

Jan 22, 2021

Jan 22, 2021

Reply to appeal

Appeal

Nov 27, 2020

Nov 24, 2020

(Electronic) Receipt

Appeal

Nov 24, 2020

Nov 24, 2020

Nov 24, 2020

Reply to appeal

Appeal

Nov 24, 2020

Nov 10, 2020

Nov 5, 2020

(Electronic) Receipt

Appeal

Nov 5, 2020

Nov 5, 2020

Nov 5, 2020

Jul 24, 2020

Jul 24, 2020

Jul 24, 2020

Jul 21, 2020

(Electronic) Receipt

Appeal

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Jul 21, 2020

Claims

Appeal

Jul 21, 2020

Jul 21, 2020

Jul 16, 2020

(Electronic) Receipt

Appeal

Jul 16, 2020

Jul 16, 2020

Jul 16, 2020

Jul 16, 2020

Jul 16, 2020

May 18, 2020

May 15, 2020

May 13, 2020

(Electronic) Receipt

Appeal

May 13, 2020

May 13, 2020

May 12, 2020

(Electronic) Receipt

Appeal

May 12, 2020

May 12, 2020

Notice of appeal

Appeal

Apr 20, 2020

Apr 10, 2020

(Electronic) Receipt

Appeal

Apr 10, 2020

Apr 10, 2020

Notice of appeal

Appeal

Mar 25, 2020

Mar 23, 2020

Mar 19, 2020

Mar 19, 2020

Mar 18, 2020

Mar 17, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Means of redress

OPPO

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Mar 16, 2020

Feb 6, 2020

Feb 6, 2020

Feb 6, 2020

Feb 6, 2020

Feb 6, 2020

Feb 6, 2020

Feb 6, 2020

Feb 6, 2020

Feb 6, 2020

Feb 6, 2020

Feb 5, 2020

Feb 5, 2020

Feb 5, 2020

Feb 5, 2020

Feb 5, 2020

Feb 5, 2020

Feb 3, 2020

Feb 3, 2020

Feb 3, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Claims

OPPO

Jan 31, 2020

Jan 31, 2020

Jan 30, 2020

Jan 30, 2020

Jan 30, 2020

Jan 30, 2020

Jan 30, 2020

Jan 30, 2020

Jan 30, 2020

Jan 30, 2020

Jan 30, 2020

Jan 24, 2020

Jan 24, 2020

Jan 24, 2020

Jan 24, 2020

Jan 24, 2020

Jan 21, 2020

Jan 21, 2020

Jan 21, 2020

Jan 21, 2020

Jan 21, 2020

Jan 21, 2020

Jan 16, 2020

Jan 16, 2020

Jan 16, 2020

Jan 16, 2020

Jan 16, 2020

Jan 13, 2020

Jan 13, 2020

Jan 13, 2020

Jan 13, 2020

Jan 13, 2020

Jan 10, 2020

Jan 10, 2020

Jan 10, 2020

Dec 20, 2019

Dec 20, 2019

Dec 20, 2019

Dec 20, 2019

Nov 25, 2019

Nov 25, 2019

Nov 25, 2019

Nov 25, 2019

Nov 25, 2019

Nov 18, 2019

Nov 18, 2019

Nov 18, 2019

Nov 18, 2019

Nov 18, 2019

Nov 8, 2019

Nov 8, 2019

Nov 8, 2019

Nov 8, 2019

Nov 8, 2019

Nov 7, 2019

Nov 7, 2019

Nov 7, 2019

Nov 7, 2019

Nov 7, 2019

Nov 7, 2019

Nov 7, 2019

Nov 7, 2019

Nov 7, 2019

Nov 7, 2019

Nov 5, 2019

Nov 5, 2019

Nov 5, 2019

Nov 5, 2019

Nov 5, 2019

Nov 5, 2019

Nov 5, 2019

Nov 5, 2019

Nov 5, 2019

Nov 5, 2019

Nov 5, 2019

Nov 4, 2019

Nov 4, 2019

Nov 4, 2019

Nov 4, 2019

Nov 4, 2019

Nov 4, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Claims

OPPO

Oct 31, 2019

Oct 31, 2019

Oct 30, 2019

Oct 30, 2019

Oct 30, 2019

Oct 29, 2019

Oct 29, 2019

Oct 29, 2019

Oct 28, 2019

Oct 28, 2019

Oct 28, 2019

Oct 28, 2019

Sep 23, 2019

Sep 23, 2019

Sep 23, 2019

Sep 23, 2019

Sep 23, 2019

Sep 17, 2019

Sep 9, 2019

Sep 9, 2019

Sep 9, 2019

Sep 9, 2019

Sep 9, 2019

Sep 9, 2019

Jul 22, 2019

Jul 22, 2019

Jul 22, 2019

Jul 22, 2019

Jul 22, 2019

Jul 16, 2019

Jul 16, 2019

Jul 16, 2019

Jul 15, 2019

Jul 8, 2019

Jul 8, 2019

Jul 8, 2019

Jul 8, 2019

Jul 8, 2019

Jul 8, 2019

Jul 3, 2019

Jun 28, 2019

Jun 28, 2019

Jun 27, 2019

Jun 27, 2019

Jun 26, 2019

Jun 26, 2019

Jun 25, 2019

Jun 25, 2019

Jun 25, 2019

Jun 24, 2019

Jun 24, 2019

Jun 19, 2019

Jun 19, 2019

Jun 19, 2019

Jun 19, 2019

Jun 19, 2019

Jun 19, 2019

Jun 19, 2019

Jun 19, 2019

Jun 19, 2019

Jun 19, 2019

Jun 19, 2019

Jun 19, 2019

Jun 19, 2019

Jun 19, 2019

Jun 19, 2019

May 23, 2019

May 23, 2019

May 23, 2019

May 23, 2019

May 23, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

May 15, 2019

Apr 8, 2019

Apr 8, 2019

Apr 8, 2019

Apr 8, 2019

Apr 8, 2019

Mar 29, 2019

Mar 29, 2019

Mar 29, 2019

Mar 29, 2019

Mar 29, 2019

Mar 29, 2019

Mar 29, 2019

Mar 29, 2019

Mar 29, 2019

Mar 29, 2019

Mar 22, 2019

Mar 22, 2019

Mar 22, 2019

Feb 18, 2019

Feb 18, 2019

Feb 18, 2019

Feb 18, 2019

Feb 18, 2019

Feb 18, 2019

Feb 12, 2019

Feb 12, 2019

Feb 12, 2019

Nov 27, 2018

Nov 27, 2018

Nov 27, 2018

Nov 27, 2018

Nov 27, 2018

Nov 27, 2018

Nov 20, 2018

Nov 20, 2018

Nov 20, 2018

Sep 18, 2018

Sep 18, 2018

Sep 18, 2018

Sep 18, 2018

Sep 18, 2018

Sep 18, 2018

Sep 11, 2018

Refund of fees

OPPO

Sep 5, 2018

Sep 5, 2018

Sep 5, 2018

Sep 5, 2018

Sep 5, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 30, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 29, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Aug 28, 2018

Dec 7, 2017

Nov 6, 2017

Decision to grant a European patent

Search/Exam

Sep 21, 2017

(Electronic) Receipt

Search/Exam

Sep 21, 2017

Filing of the translations of the claims

Search/Exam

Sep 21, 2017

French translation of claims

Search/Exam

Sep 21, 2017

German translation of the claims

Search/Exam

Sep 21, 2017

Letter accompanying subsequently filed items

Search/Exam

Aug 2, 2017

Aug 2, 2017

Aug 2, 2017

Intention to grant (signatures)

Search/Exam

Aug 2, 2017

Text intended for grant (clean copy)

Search/Exam

Aug 2, 2017

Jul 13, 2016

Jul 7, 2016

Mar 1, 2016

(Electronic) Receipt

Search/Exam

Mar 1, 2016

Amended description with annotations

Search/Exam

Mar 1, 2016

Description

Search/Exam

Mar 1, 2016

Letter accompanying subsequently filed items

Search/Exam

Mar 1, 2016

Feb 11, 2016

Jan 28, 2016

Payment of fees and costs

Search/Exam

Jan 28, 2016

Dec 1, 2015

Annex to the communication

Search/Exam

Dec 1, 2015

Communication from the Examining Division

Search/Exam

Apr 30, 2015

Apr 30, 2015

Apr 2, 2015

Mar 25, 2015

(Electronic) Receipt

Search/Exam

Mar 25, 2015

Letter accompanying subsequently filed items

Search/Exam

Mar 25, 2015

Aug 2, 2013

Aug 1, 2013

Jul 29, 2013

Apr 12, 2013

Amended claims with annotations

Search/Exam

Apr 12, 2013

Claims

Search/Exam

Apr 12, 2013

Apr 4, 2013

Amended claims with annotations

Search/Exam

Apr 4, 2013

Claims

Search/Exam

Apr 4, 2013

Dec 6, 2012

Annex to the communication

Search/Exam

Dec 6, 2012

Communication from the Examining Division

Search/Exam

Aug 28, 2009

Letter concerning the inventor

Search/Exam

Aug 27, 2009

Letter concerning the inventor

Search/Exam

Aug 6, 2009

Jul 30, 2009

Letter which had not been notified

Search/Exam

Jul 27, 2009

Jul 17, 2009

Letter which had not been notified

Search/Exam

Jul 15, 2009

Jul 14, 2009

May 11, 2009

May 11, 2009

May 8, 2009

May 8, 2009

Apr 21, 2009

Notification of the recording of a change

Search/Exam

Apr 16, 2009

Request for entry into the European phase

Search/Exam

Apr 10, 2009

Fax request to enter the European phase

Search/Exam

Mar 13, 2009

Information on entry into European phase

Search/Exam

Feb 11, 2009

Feb 11, 2009

Feb 11, 2009

Feb 11, 2009

Feb 11, 2009

Feb 11, 2009

Feb 11, 2009

Feb 11, 2009

Feb 11, 2009

Jun 24, 2008

Notification of election of EPO

Search/Exam

May 21, 2008

May 21, 2008

May 19, 2008

PCT demand form

PCT2

May 19, 2008

May 19, 2008

May 19, 2008

May 19, 2008

May 15, 2008

May 15, 2008

PCT demand form

PCT2

May 15, 2008

May 15, 2008

May 15, 2008

May 15, 2008

May 15, 2008

May 8, 2008

Copy of the international search report

Search/Exam

May 8, 2008

Published international application - A1

Search/Exam

Apr 14, 2008

Apr 6, 2007

Apr 5, 2007

Abstract

PCTISA

Apr 5, 2007

Claims

PCTISA

Apr 5, 2007

Description

PCTISA

Apr 5, 2007

Drawings

PCTISA

Apr 5, 2007

Mar 21, 2007