The weekly litigation news digest is live. Subscribe now

Method To Manufacture A Recycled Pet-Based Foam Material - EP3775008

The patent EP3775008 was granted to Point Plastic on May 1, 2024. The application was filed on Mar 29, 2019 under application number EP19721387A. The patent is currently recorded with a legal status of "Granted And Under Opposition".

EP3775008

- Application Number

- EP19721387A

- Filing Date

- Mar 29, 2019

- Status

- Granted And Under Opposition

- Mar 29, 2024

- Publication Date

- May 1, 2024

- External Links

- Slate, Register, Google Patents

Patent Summary

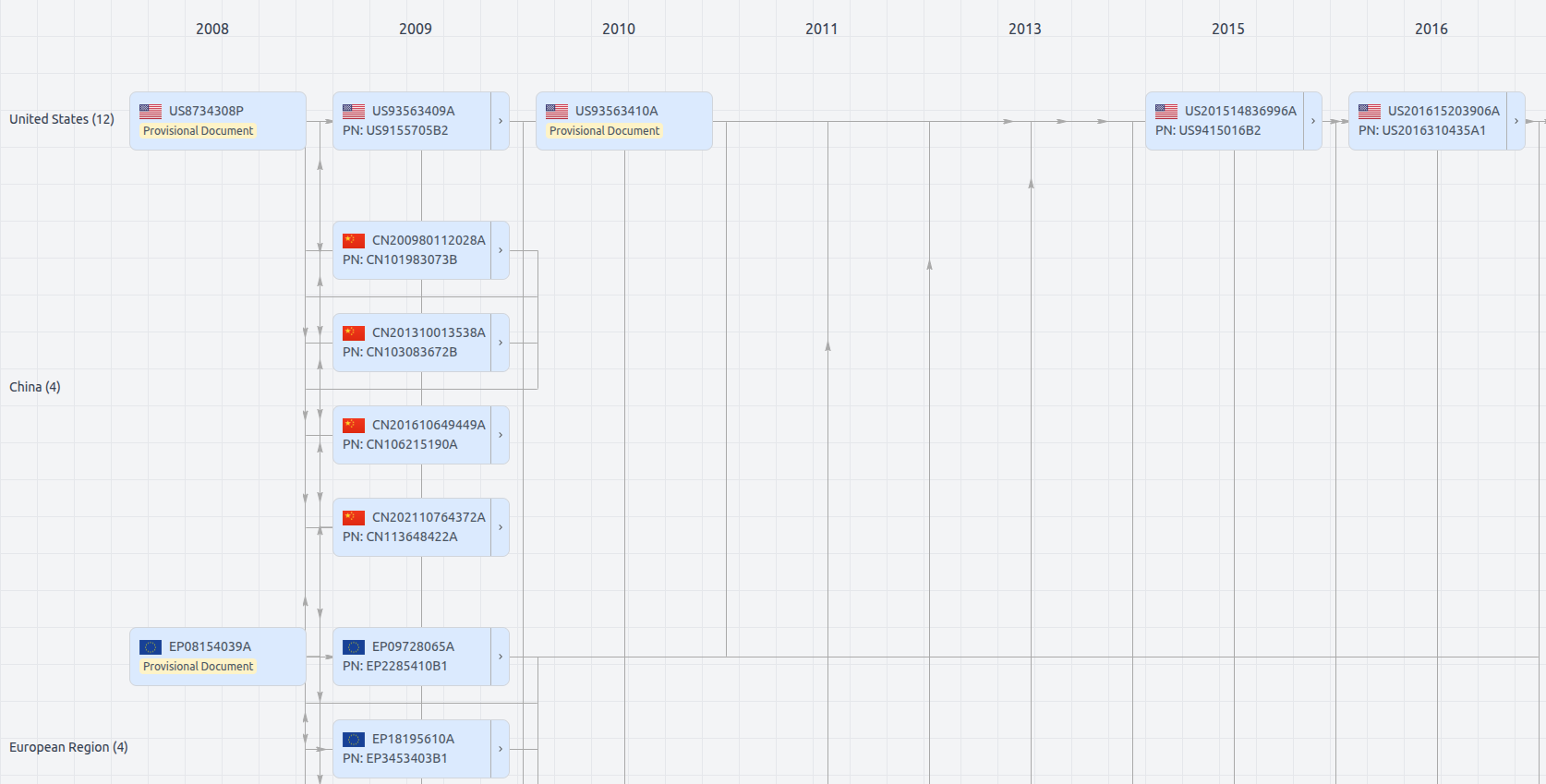

Patent Family

Patent Oppositions

Patent oppositions filed by competitors challenge the validity of a granted patent. These oppositions are typically based on claims of prior art, lack of novelty, or non-obviousness. They are a key part of the process for determining a patent's strength and enforceability.

Patent Citations (8) New

Patent citations refer to prior patents cited during different phases such as opposition or international search.

Dossier Documents

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents