Interlayer For Laminated Glass And Laminated Glass

Patent No. US10913244 (titled "Interlayer For Laminated Glass And Laminated Glass") was filed by Sekisui Chemical Co Ltd on Sep 28, 2016.

What is this patent about?

’244 is related to the field of interlayer films for laminated glass , particularly those used in applications like automotive windshields with head-up displays (HUD). Laminated glass, composed of a polymer interlayer sandwiched between two glass sheets, enhances safety by minimizing scattering upon impact. Wedge-shaped interlayers are used to correct for double images in HUDs, but their varying thickness can lead to wrinkle formation, especially when the film is stored in rolls.

The underlying idea behind ’244 is to control the thermal shrinkage properties of a wedge-shaped interlayer film to minimize wrinkle formation. The insight is that by ensuring a relatively uniform thermal shrinkage profile across the film's width, despite its varying thickness, the stress buildup that causes wrinkles can be mitigated. This is achieved by limiting the difference between the maximum and minimum thermal shrinkage ratios measured at specific points along the film's width.

The claims of ’244 focus on an interlayer film for laminated glass with a machine direction (MD) and a transverse direction (TD), where one end is thicker than the other, creating a wedge shape. Crucially, the absolute difference between the largest and smallest thermal shrinkage ratios, measured at three points along the MD (0.05X, 0.5X, and 0.95X, where X is the distance between the ends), must be 15% or less. The film contains a polyvinyl acetal resin .

In practice, the invention involves carefully controlling the manufacturing process to achieve the desired thermal shrinkage uniformity. This can be done by adjusting parameters like the temperature and tension applied to the film during extrusion and cooling. The use of a polyvinyl acetal resin is important, as it provides the necessary flexibility and adhesion to the glass layers. The limited thermal shrinkage variation ensures that when the film is heated during lamination or stored in a roll, it shrinks evenly, preventing wrinkle formation and maintaining a smooth appearance in the final laminated glass product.

This approach differs from prior art that focused solely on the wedge shape for HUD correction, without addressing the wrinkle problem. By specifically targeting the thermal shrinkage profile, ’244 provides a more robust solution that improves the manufacturing yield and the visual quality of laminated glass, especially in demanding applications like automotive windshields. The controlled thermal shrinkage allows for easier handling and processing of the interlayer film, reducing waste and improving the overall efficiency of laminated glass production.

How does this patent fit in bigger picture?

Technical landscape at the time

In the mid-2010s when ’244 was filed, laminated glass was widely used in automotive and building applications, at a time when interlayer films were commonly made of polyvinyl acetal resins. Achieving consistent thermal shrinkage in wedge-shaped interlayer films, where thickness varies across the film, was non-trivial due to the tendency to form wrinkles during manufacturing and heating processes.

Novelty and Inventive Step

The examiner approved the application because the closest prior art, US 3,488,715, does not teach or suggest the claimed thermal shrinkage ratio being greater than 0%. The reference teaches a uniform shrinkage amount across the product, and it would not have been obvious to modify the sheet to obtain varied shrinkage amounts across the sheet.

Claims

This patent contains 17 claims, with claim 1 being independent. The independent claim focuses on an interlayer film for laminated glass, defining it by its composition (polyvinyl acetal resin) and specific thermal shrinkage ratio requirements at different positions along its length. The dependent claims generally elaborate on the composition, structure (e.g., multiple layers), and manufacturing process of the interlayer film, as well as a laminated glass incorporating the film.

Key Claim Terms New

Definitions of key terms used in the patent claims.

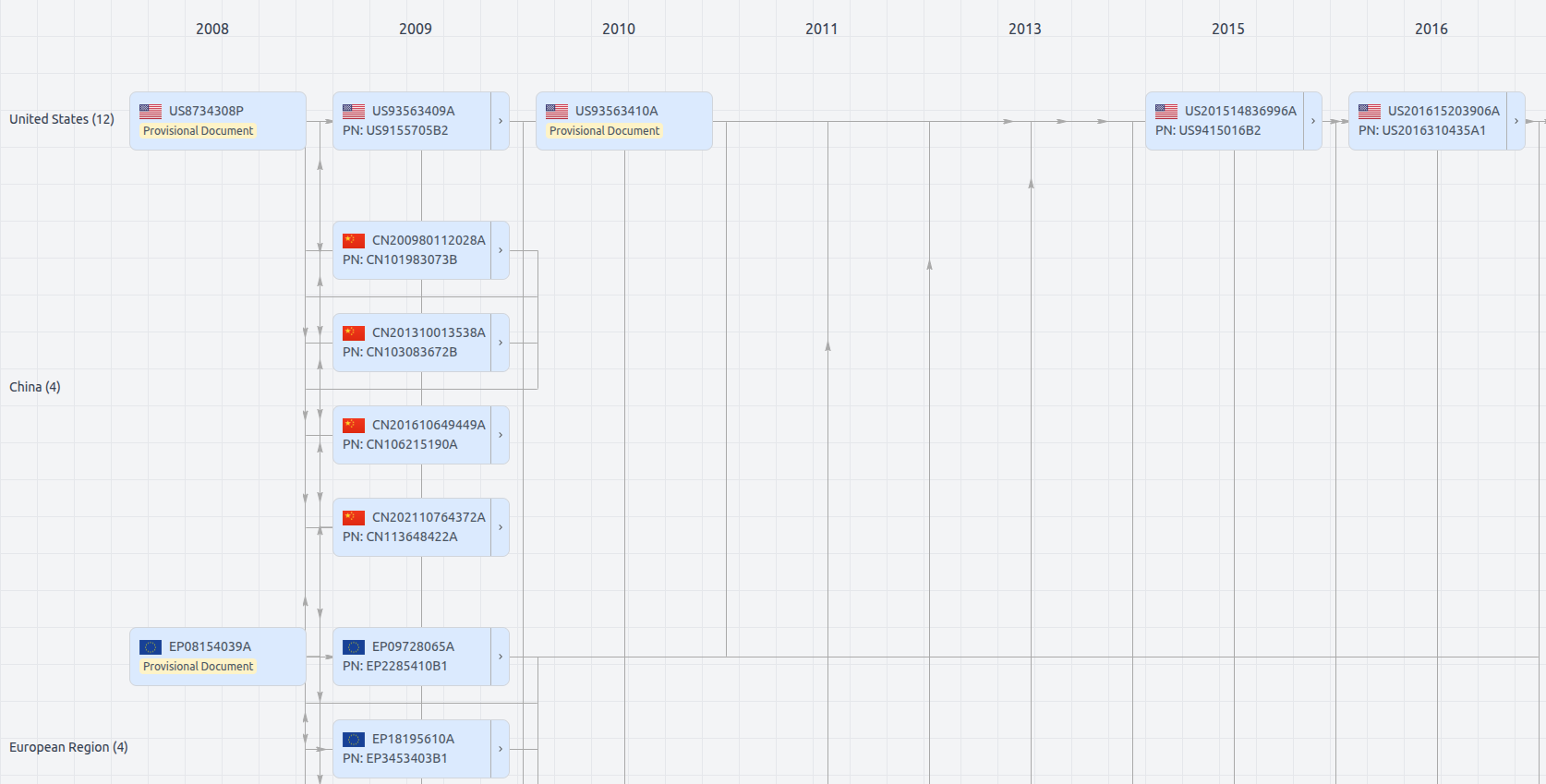

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US10913244

- Application Number

- US15761803

- Filing Date

- Sep 28, 2016

- Status

- Granted

- Expiry Date

- Sep 28, 2036

- External Links

- Slate, USPTO, Google Patents