Hub-Less And Nut-Less Turbine Wheel And Compressor Wheel Design For Turbochargers

Patent No. US10914231 (titled "Hub-Less And Nut-Less Turbine Wheel And Compressor Wheel Design For Turbochargers") was filed by Apexturbo Llc on May 16, 2019.

What is this patent about?

’231 is related to the field of turbochargers for internal combustion engines. Turbochargers increase engine efficiency by forcing more air into the combustion chamber. Traditional designs include a hub with a large nut on both the turbine and compressor wheels, used during manufacturing and assembly. These nuts, however, obstruct airflow, limiting horsepower, especially in high-performance applications where regulations may restrict turbocharger size.

The underlying idea behind ’231 is to improve turbocharger efficiency by removing the central nut on the turbine and/or compressor wheels. This nut-less design eliminates airflow obstructions, allowing for increased blade length and optimized blade geometry. The removal of the nut does not compromise structural integrity, as the blade strength does not rely on the hub's center. This modification allows for greater horsepower output without increasing the turbocharger's frame size.

The claims of ’231 focus on a turbocharger having a turbine wheel and/or a compressor wheel with blades whose leading edges converge at an apex aligned with the centerline of the shaft. Specifically, the claims require that the leading edges extend helically from an inboard point to an outboard point, and that the inboard points are positioned closer to the centerline than the radius of the shaft. This apex design is the key feature distinguishing the claimed invention.

In practice, the turbine and compressor wheels are manufactured by machining, casting, forging, or milling. A finishing operation removes the traditional nut or hub, creating the apex where the blade leading edges converge. The wheels are then mounted to the shaft, either by welding or using a threaded connection and a set screw. The set screw prevents over-tightening of the compressor wheel, which can damage the shaft and bearings.

This design differs from prior approaches by eliminating the airflow obstruction caused by the central nut. By maximizing fluid flow and blade length, the turbocharger's efficiency and horsepower output are significantly increased . This is particularly advantageous in applications where turbocharger size is restricted, such as motorsports, allowing for greater power within the same physical footprint. The nut-less design also reduces weight and improves throttle response.

How does this patent fit in bigger picture?

Technical landscape at the time

In the late 2010s when ’231 was filed, turbochargers were commonly used to increase the power output of internal combustion engines by forcing more air into the combustion chamber. At a time when turbocharger designs typically included a hex nut or fastener on the compressor and turbine wheels for manufacturing and assembly purposes, the removal of such a nut was non-trivial due to concerns about structural integrity and manufacturing constraints.

Novelty and Inventive Step

The patent was approved because the examiner determined that the prior art did not disclose inboard points of the leading edges of the blades positioned closer to the centerline of the shaft than the radius of the shaft.

Claims

This patent contains 14 claims, with independent claims 1, 11, and 13. The independent claims focus on a turbocharger, a turbine wheel for a turbocharger, and a compressor wheel, respectively, each having blades with leading edges converging at an apex aligned with the centerline. The dependent claims generally add specific details and limitations to the independent claims, further defining the features and configurations of the turbocharger, turbine wheel, and compressor wheel.

Key Claim Terms New

Definitions of key terms used in the patent claims.

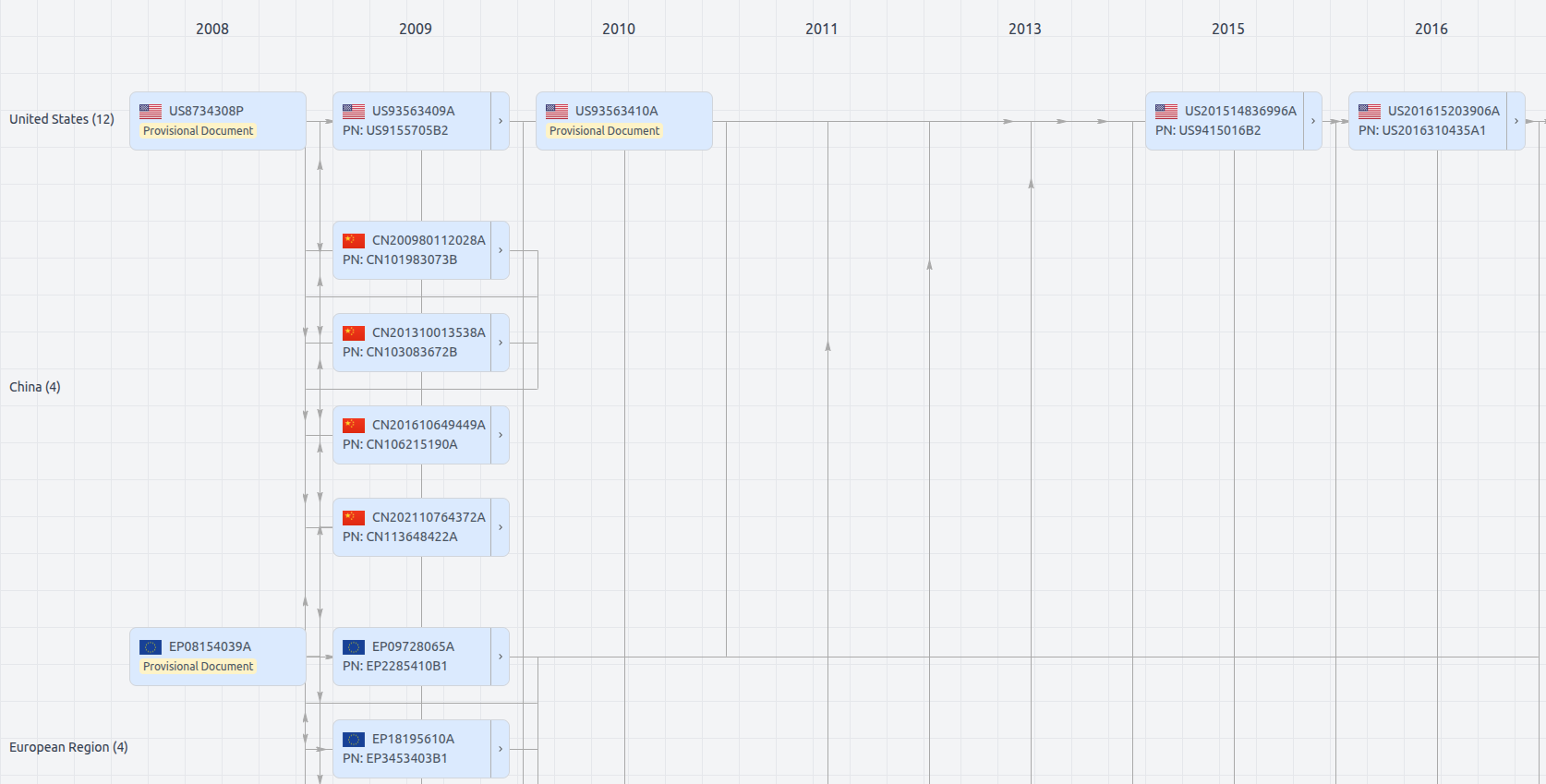

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US10914231

- Application Number

- US16413952

- Filing Date

- May 16, 2019

- Status

- Granted

- Expiry Date

- May 27, 2039

- External Links

- Slate, USPTO, Google Patents