Fence Installation Method

Patent No. US10954687 (titled "Fence Installation Method") was filed by Swi Llc on Mar 27, 2018.

What is this patent about?

’687 is related to the field of fence installation , specifically addressing the problem of time-consuming and labor-intensive methods that require digging holes and using concrete to set fence posts. Traditional fence installation is often hampered by frozen ground, inclement weather, and the mess created by digging and concrete spillage.

The underlying idea behind ’687 is to simplify fence installation by using a system where beams are driven directly into the ground, eliminating the need for digging. The key inventive insight is that tubular posts can then be slid over these beams, and the interaction between the beam and the tube ensures that the post automatically attains a substantially vertical orientation without requiring separate leveling structures.

The claims of ’687 focus on a method comprising driving beams into the ground, sliding tubes over the beams to achieve vertical alignment, and connecting the tubes with rails. The independent claims emphasize the absence of additional leveling structures between the beams and tubes, and the use of longitudinal channels in the beams to align and support the rails.

In practice, the method involves driving I-beams into the ground using a mallet or similar tool. The I-beams have longitudinal channels that run along their length. Tubular posts with corresponding holes are then slid over the I-beams. As the tube slides down, the beam's outer surfaces engage the tube's inner surfaces, automatically aligning the tube vertically. Horizontal rails are then inserted through the holes in the tubes, with the rail ends projecting into the longitudinal channels of the I-beams.

This method differentiates itself from prior approaches by eliminating the need for digging holes and using concrete. The direct driving of beams and the self-aligning nature of the tubular posts significantly reduce installation time and labor. The use of longitudinal channels provides a secure and straightforward way to connect the rails to the posts, further simplifying the installation process and reducing waste.

How does this patent fit in bigger picture?

Technical landscape at the time

In the late 2010s when ’687 was filed, at a time when fence posts were typically installed by digging holes and filling them with concrete, a process that was often tedious and time-consuming, especially in regions with frost lines or during cold weather when concrete setting could be problematic.

Novelty and Inventive Step

The examiner approved the patent because the prior art of record failed to teach or fairly disclose a method that includes a first beam with a longitudinal channel and a second beam with a longitudinal channel facing the first, a first hole aligning with the first channel and facing the second channel, tilting a first rail so that the second rail end is farther from the ground than the first, with the second tube elevated above the first beam, sliding the second tube toward the ground so that the second top moves toward the level of the first beam, and securing the first tube at a first fixed elevation and the second tube at a second fixed elevation.

Claims

There are 20 claims in total. Claims 1, 10, and 20 are independent. The independent claims are directed to methods of installing a fence using beams, tubes, and rails. The dependent claims generally add further detail and limitations to the method steps recited in the independent claims.

Key Claim Terms New

Definitions of key terms used in the patent claims.

Litigation Cases New

US Latest litigation cases involving this patent.

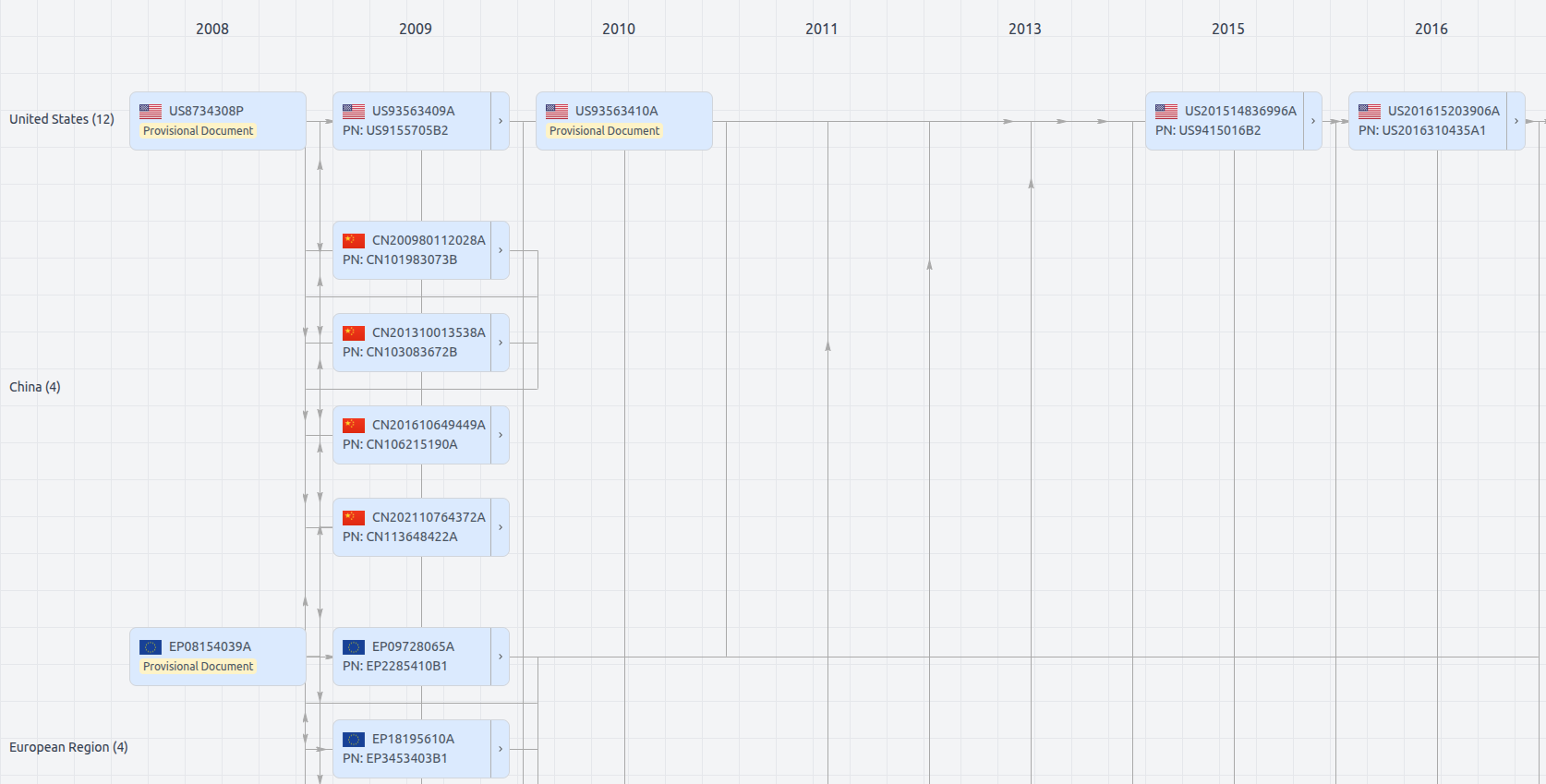

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US10954687

- Application Number

- US15937274

- Filing Date

- Mar 27, 2018

- Status

- Granted

- Expiry Date

- Dec 19, 2039

- External Links

- Slate, USPTO, Google Patents