Adhesive Dispensing System And Method

Patent No. US11559820 (titled "Adhesive Dispensing System And Method") was filed by 4 Cs Spray Equipment Rental Llc on Jul 1, 2020.

What is this patent about?

’820 is related to the field of adhesive dispensing systems, specifically those used for applying multi-component adhesives in construction applications like roofing and carpeting. Traditional systems either use high-pressure sprays, which are expensive and messy, or low-pressure beads, which provide uneven coverage. These systems also suffer from clogging issues due to adhesive hardening within the dispensing head.

The underlying idea behind ’820 is to introduce pressurized air into the individual adhesive component streams *before* they are mixed. This aeration step serves two purposes: it further pressurizes the fluids, enabling a low-pressure aerated spray, and it introduces air bubbles into the components, leading to a more uniform and controllable adhesive application.

The claims of ’820 focus on a method for dispensing two-component adhesives. This involves flowing the two components through separate passages in a dispensing head, then aerating at least one of the components *before* they enter a mixing tip. The components are then mixed within the tip and dispensed as an adhesive.

In practice, the system uses a proportioning pump to initially pressurize the adhesive components. Then, pressurized air is injected into each component stream via dedicated air inlets in the dispensing head. The amount of air injected is regulated to control the degree of aeration and additional pressurization. This allows the system to switch between a bead application (no aeration) and a low-pressure aerated spray application, simply by adjusting the airflow.

This approach differs from prior art high-pressure spray systems by using significantly lower pressures, resulting in less overspray and reduced operator exposure to atomized adhesive. It also improves mixing thoroughness, leading to a cured adhesive with a finer cell structure, which enhances adhesion. Furthermore, the system incorporates an air purging feature to clear the dispensing head and mixing tip after use, preventing clogging.

How does this patent fit in bigger picture?

Technical landscape at the time

In the late 2010s when ’820 was filed, two-component adhesive dispensing systems were known, at a time when such systems commonly relied on proportioning pumps to move resin and hardener components from supply reservoirs to a dispensing head. At that time, systems typically combined the components within a disposable static mixer tip. It was also known to apply adhesives in either a high-pressure spray or a low-pressure bead form, where hardware constraints made it non-trivial to achieve both uniform coverage and controlled application without expensive high-pressure systems.

Novelty and Inventive Step

The examiner approved the application because the prior art (Keller US 6260577, Chabria US 4428530, and Hunter US 6616068) did not teach all the limitations of the claims. Specifically, the prior art failed to disclose discharging an adhesive by aerating it, followed by all the lines and passages in a dispensing head and mixing tip. The examiner stated that there was no apparent reason or motivation to modify the prior art to arrive at the claimed invention.

Claims

This patent contains 38 claims, with independent claims numbered 1, 13, 23, and 32. The independent claims are directed to methods for dispensing first and second adhesive component fluids using a dispensing head and mixing tip. The dependent claims generally elaborate on specific features, conditions, or steps related to the aeration, pressurization, and regulation of fluid flow within the methods described in the independent claims.

Key Claim Terms New

Definitions of key terms used in the patent claims.

Litigation Cases New

US Latest litigation cases involving this patent.

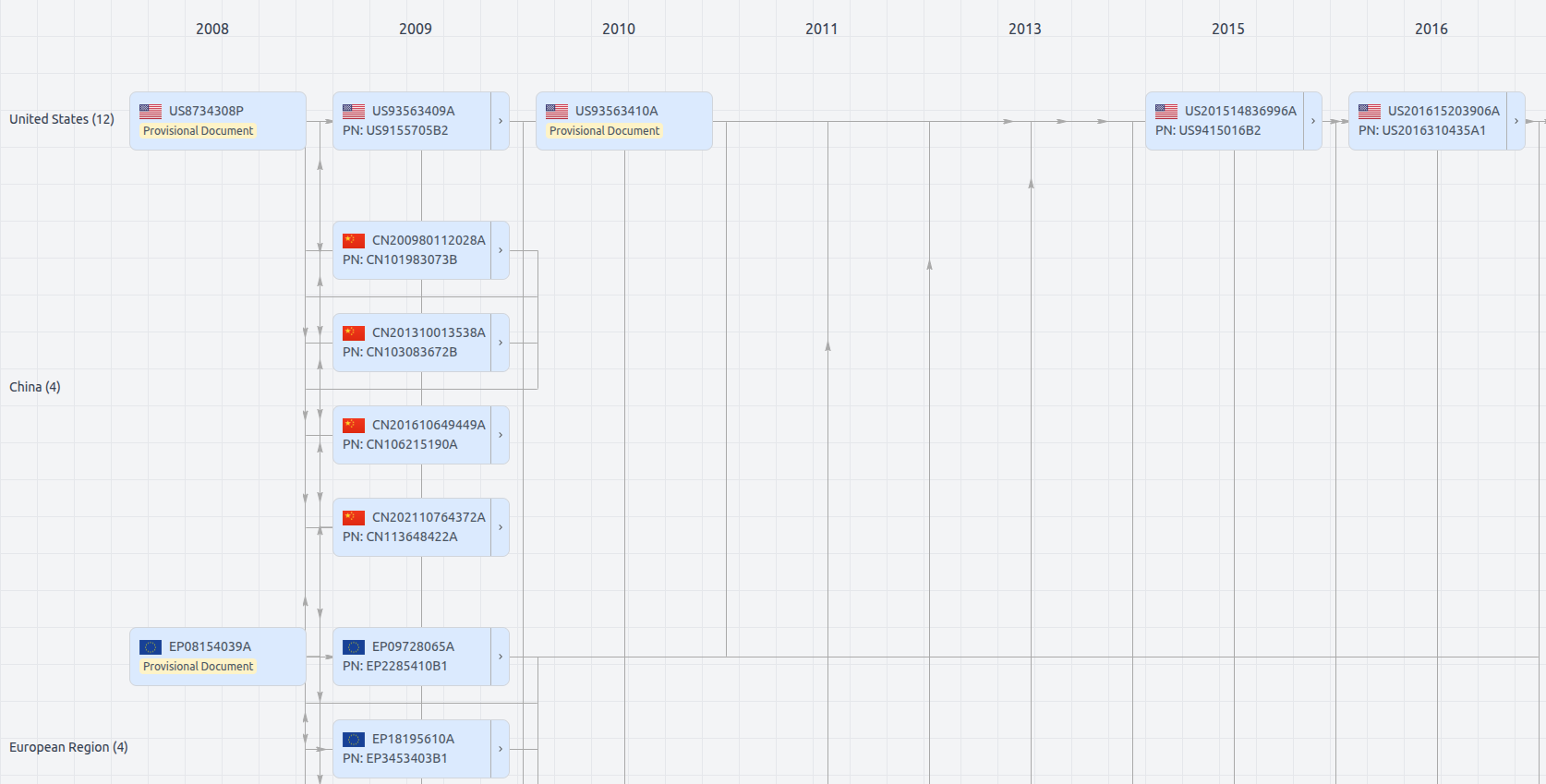

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US11559820

- Application Number

- US16918340

- Filing Date

- Jul 1, 2020

- Status

- Granted

- Expiry Date

- Oct 29, 2039

- External Links

- Slate, USPTO, Google Patents