Hub-Less And Nut-Less Turbine Wheel And Compressor Wheel Designs And Installation/Removal Tool

Patent No. US11598294 (titled "Hub-Less And Nut-Less Turbine Wheel And Compressor Wheel Designs And Installation/Removal Tool") was filed by Apexturbo Llc on Mar 1, 2021.

What is this patent about?

’294 is related to the field of forced induction devices, such as turbochargers and superchargers, used to increase the efficiency and power output of internal combustion engines. Traditional designs often incorporate a hex nut or similar fastener on the compressor wheel for manufacturing and assembly purposes. This nut, however, obstructs airflow, limiting horsepower, especially in high-performance applications. The patent addresses the need for improved designs that maximize airflow and increase power output without increasing the size of the forced induction device.

The underlying idea behind ’294 is to eliminate the central nut on the compressor wheel of a turbocharger or supercharger and instead use through-bores in the wheel's body to engage with a specialized tool for installation and removal. This removes the airflow obstruction caused by the nut, allowing for a more streamlined design and increased airflow. The compressor wheel is threadably mounted on the shaft, and the tool engages the through-bores to rotate the wheel during assembly and disassembly without applying pressure to the blades.

The claims of ’294 focus on a forced induction device featuring a compressor wheel with an internally threaded bore that mates with a threaded shaft. Crucially, the claims require at least one through-bore offset from the shaft's centerline, designed to receive a post from a specialized tool. This tool temporarily locks with the compressor wheel, enabling rotation relative to the shaft for installation and removal. The claims also cover a forced induction device with a compressor wheel, a turbine wheel, a shaft, and a housing, where the compressor wheel has at least one through bore for the tool.

In practice, the compressor wheel is manufactured with one or more through-bores located away from the central axis. A tool with corresponding posts is then used to engage these bores, allowing a technician to rotate the compressor wheel relative to the shaft. This threading action either secures or removes the wheel from the shaft. Because the tool engages the wheel through these dedicated bores, the fragile compressor blades are not subjected to damaging forces during installation or removal.

This design differentiates itself from prior approaches by removing the need for a central nut or hub, which traditionally served as the tool interface. By eliminating this obstruction, the design maximizes the blade surface area and improves airflow through the compressor. The use of through-bores and a specialized tool provides a more efficient and less damaging method for installing and removing the compressor wheel, leading to increased horsepower and improved serviceability. The tool-less apex of the compressor wheel minimizes flow disruption.

How does this patent fit in bigger picture?

Technical landscape at the time

In the late 2010s when ’294 was filed, forced induction systems were commonly implemented using compressor and turbine wheels with a central hex nut or fastener for manufacturing and assembly. At a time when hardware constraints made increasing engine power non-trivial, designs often relied on optimizing existing turbocharger or supercharger configurations.

Novelty and Inventive Step

Claims 1-11 and 18-20 were pending. Claims 1, 6, and 8 were rejected, but later withdrawn. Claims 1-11 were rejected for nonstatutory double patenting. A terminal disclaimer filed by the applicant was disapproved. The Office action was made final. The prosecution record does not describe the technical reasoning or specific claim changes that led to allowance.

Claims

This patent contains 11 claims, with claims 1 and 10 being independent. The independent claims are directed to a forced induction device for an internal combustion engine, focusing on the compressor wheel's mounting to the shaft and a tool for installation/removal. The dependent claims generally elaborate on specific features and configurations of the compressor wheel, blades, through bores, and the tool used with the forced induction device.

Key Claim Terms New

Definitions of key terms used in the patent claims.

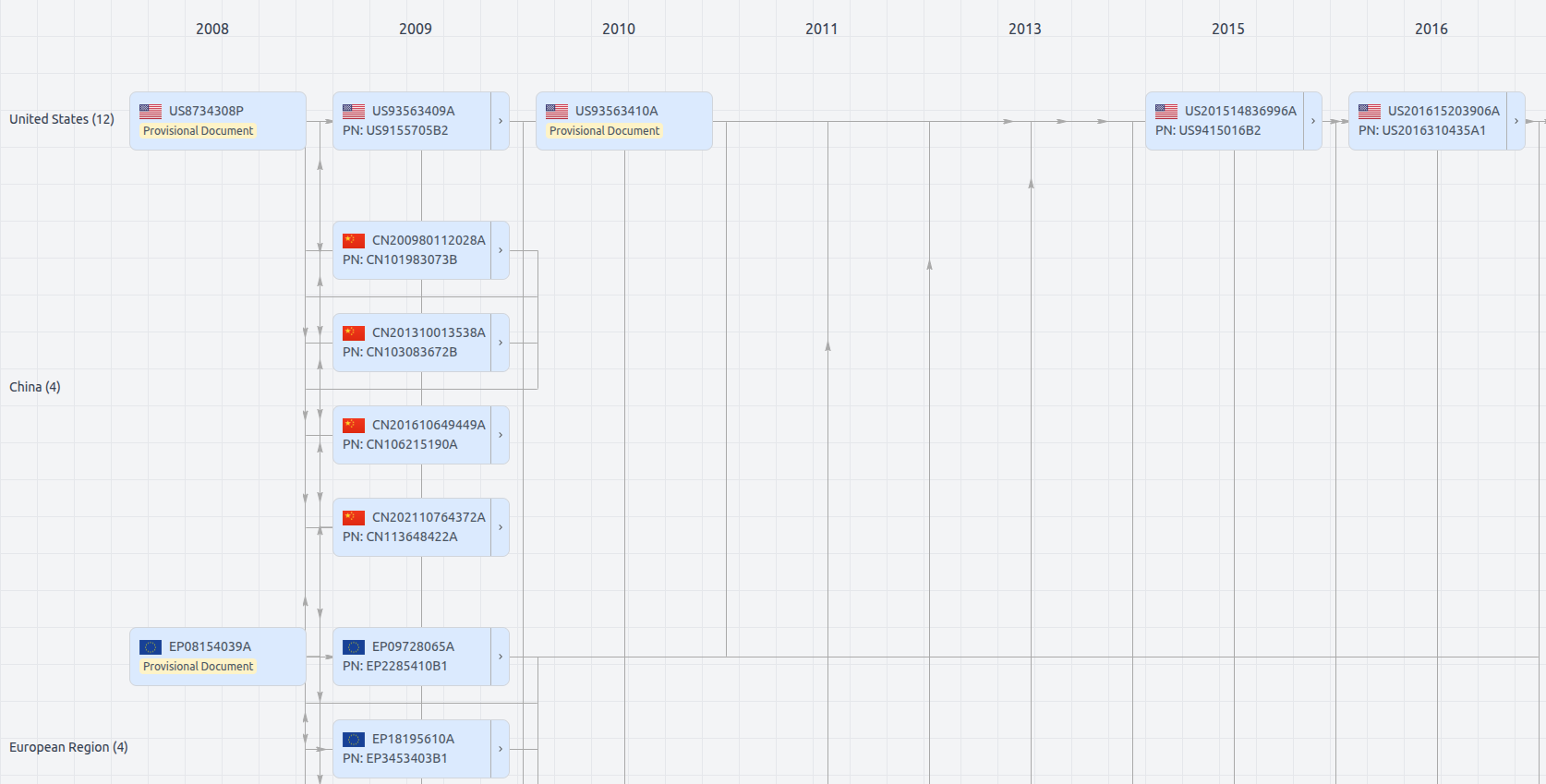

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US11598294

- Application Number

- US17188371

- Filing Date

- Mar 1, 2021

- Status

- Granted

- Expiry Date

- May 16, 2039

- External Links

- Slate, USPTO, Google Patents