Biodegradable, Industrially Compostable, And Recyclable Injection Molded Microcellular Flexible Foams

Patent No. US11718055 (titled "Biodegradable, Industrially Compostable, And Recyclable Injection Molded Microcellular Flexible Foams") was filed by Ing Capital Llc on Oct 7, 2022.

What is this patent about?

’055 is related to the field of manufacturing flexible foams, specifically addressing the environmental concerns associated with traditional foam production. Conventional flexible foams often rely on non-renewable resources, chemical blowing agents, and crosslinking, leading to materials that are difficult to recycle or biodegrade and contribute to landfill waste.

The underlying idea behind ’055 is to create a recyclable flexible foam using a modified injection molding process. This involves using a thermoplastic polymer derived from recyclable materials and a supercritical fluid (SCF) , such as nitrogen or carbon dioxide, as a physical foaming agent instead of chemical blowing agents. The key is to form a single-phase solution of the polymer and SCF, inject it into a mold, and control the foaming process with gas counter pressure.

The claims of ’055 focus on a method for manufacturing a flexible foam. This method involves forming a molten polymer from a recyclable thermoplastic masterbatch, mixing it with a supercritical fluid to create a single-phase solution, introducing this solution into a mold cavity, foaming the solution by allowing the supercritical fluid to come out of solution, and pressurizing the mold cavity with a counterpressure gas . The dosing and hold time of this counterpressure gas are controlled by a computer based on pressure sensor data.

In practice, the thermoplastic polymer, potentially derived from recycled sources like fishing nets or carpet fibers, is melted and mixed with the SCF in a modified injection molding machine. The SCF, acting as a blowing agent, creates the foam structure. The gas counter pressure is crucial for controlling the expansion of the foam, ensuring a smooth surface finish and preventing defects. Dynamic mold temperature control further optimizes the cell structure of the foam.

This approach differs significantly from traditional foam manufacturing, which often uses chemical blowing agents that result in crosslinked polymers, making recycling difficult. By using a physical blowing agent (SCF) and carefully selected thermoplastic polymers, ’055 enables the creation of a flexible foam that can be depolymerized and recycled back into its constituent monomers, closing the loop and reducing reliance on virgin materials. The resulting foam can be used in various applications, including footwear, furniture, and automotive components.

How does this patent fit in bigger picture?

Technical landscape at the time

In the late 2010s when ’055 was filed, flexible foams were typically manufactured using non-renewable materials and chemical blowing agents. At a time when crosslinking was commonly used to achieve desired foam properties, the resulting products were often not biodegradable, compostable, or recyclable. The industry standard relied on petrochemical-derived polymers, and hardware or software constraints made it non-trivial to produce foams with both high performance and environmental sustainability.

Novelty and Inventive Step

The examiner approved the application because the prior art does not teach a method for manufacturing a flexible foam that includes: forming a molten polymer from a thermoplastic masterbatch comprising recyclable thermoplastic polymers; mixing a supercritical fluid with the molten polymer to create a single-phase solution; introducing the single-phase solution into a mold cavity with at least one pressure sensor; foaming the single-phase solution by allowing the supercritical fluid to come out of solution; and pressurizing the mold cavity with a counterpressure gas controlled by a computer-controller receiving data from the pressure sensor.

Claims

This patent contains 20 claims, with claim 1 being the only independent claim. Independent claim 1 is directed to a method for manufacturing a flexible foam using a thermoplastic masterbatch and supercritical fluid. The dependent claims elaborate on specific materials, conditions, and features of the method described in the independent claim.

Key Claim Terms New

Definitions of key terms used in the patent claims.

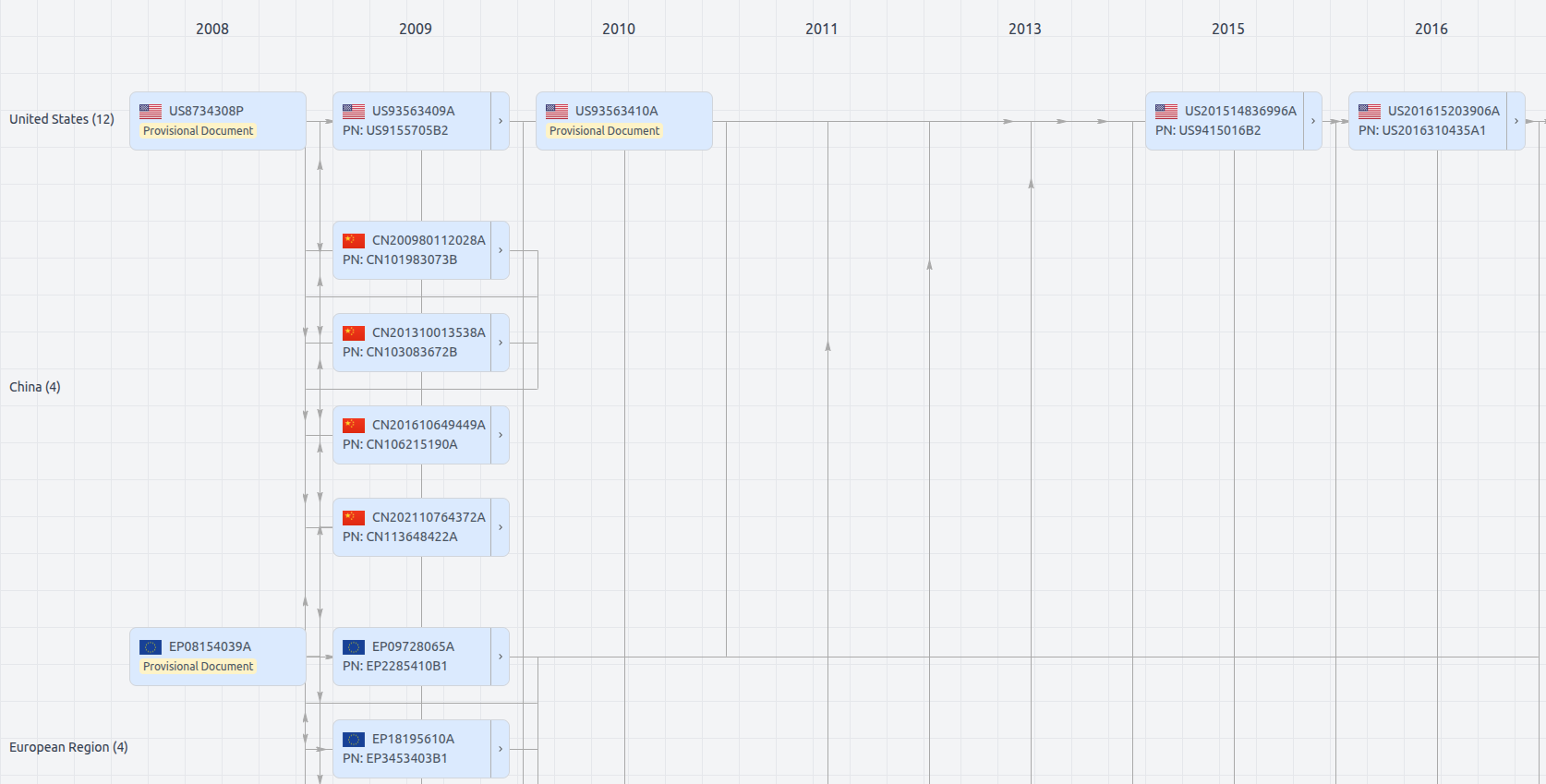

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US11718055

- Application Number

- US17938790

- Filing Date

- Oct 7, 2022

- Status

- Granted

- Expiry Date

- May 21, 2039

- External Links

- Slate, USPTO, Google Patents