Wear Plate For A Drill Pump

Patent No. US11732709 (titled "Wear Plate For A Drill Pump") was filed by Gd Energy Products Llc on Nov 22, 2021.

What is this patent about?

’709 is related to the field of high-pressure fluid pumps, specifically those used in drilling operations. These pumps utilize reciprocating pistons to generate the high pressures required for drilling. A critical component is the wear plate assembly , which provides a fluid path and sealing between the pump housing and the piston. Maintaining a reliable seal in this high-pressure environment is essential to prevent leaks and ensure efficient pump operation.

The underlying idea behind ’709 is to provide a dual-seal wear plate assembly for a drill pump, offering redundancy and extended operational life. The design incorporates both a primary radial seal and a secondary axial seal. This allows for continued operation even if the primary seal fails, by engaging the secondary seal without requiring immediate pump disassembly and repair.

The claims of ’709 focus on a wear plate assembly with a wear plate that has an annular cross-section, a radial outer seal surface, an annular seal groove, and a shoulder extending radially outward. Claim 1 recites the physical structure of the wear plate itself, emphasizing the annular seal groove for the primary radial seal and the shoulder for the secondary axial seal. Claim 9 focuses on a method of replacing a radial seal with an axial seal. Claim 15 focuses on the wear plate itself, including a relief groove.

In practice, the wear plate assembly is installed in the fluid end bore of the drill pump. The primary radial seal, seated in the annular groove, initially provides the fluid-tight seal. If this seal degrades or fails due to the high-pressure environment, the assembly can be removed, and an axial seal is placed against the shoulder of the wear plate. Re-inserting the assembly then compresses the axial seal between the shoulder and the pump housing, creating a new seal.

This design differentiates itself from traditional single-seal wear plates by providing a backup sealing mechanism . Instead of an immediate shutdown and repair when the primary seal fails, the secondary seal allows for continued operation, reducing downtime and maintenance costs. The relief groove provides compressive relief for the secondary seal, improving its effectiveness and longevity in the high-pressure environment.

How does this patent fit in bigger picture?

Technical landscape at the time

In the mid-2010s when ’709 was filed, drilling pumps at a time when were typically implemented using reciprocating plungers or pistons to provide high pressure fluid for drilling operations. At a time when systems commonly relied on radial seals, wear plate assemblies were a critical component in maintaining the integrity and efficiency of these pumps.

Novelty and Inventive Step

The claims in this application were rejected in a non-final office action. Claims 1-20 were rejected under 35 U.S.C. 102(a)(1) as being anticipated by prior art. Claim 15 was also objected to due to informalities. The prosecution record does not describe the technical reasoning or specific claim changes that led to allowance.

Claims

There are 20 claims in total. Claims 1, 9, and 15 are independent. Independent claims 1 and 15 are directed to wear plates and wear plate assemblies for drill pumps, while independent claim 9 is directed to a method of using a wear plate assembly in a drill pump. The dependent claims generally elaborate on the features, configurations, and steps of the independent claims.

Key Claim Terms New

Definitions of key terms used in the patent claims.

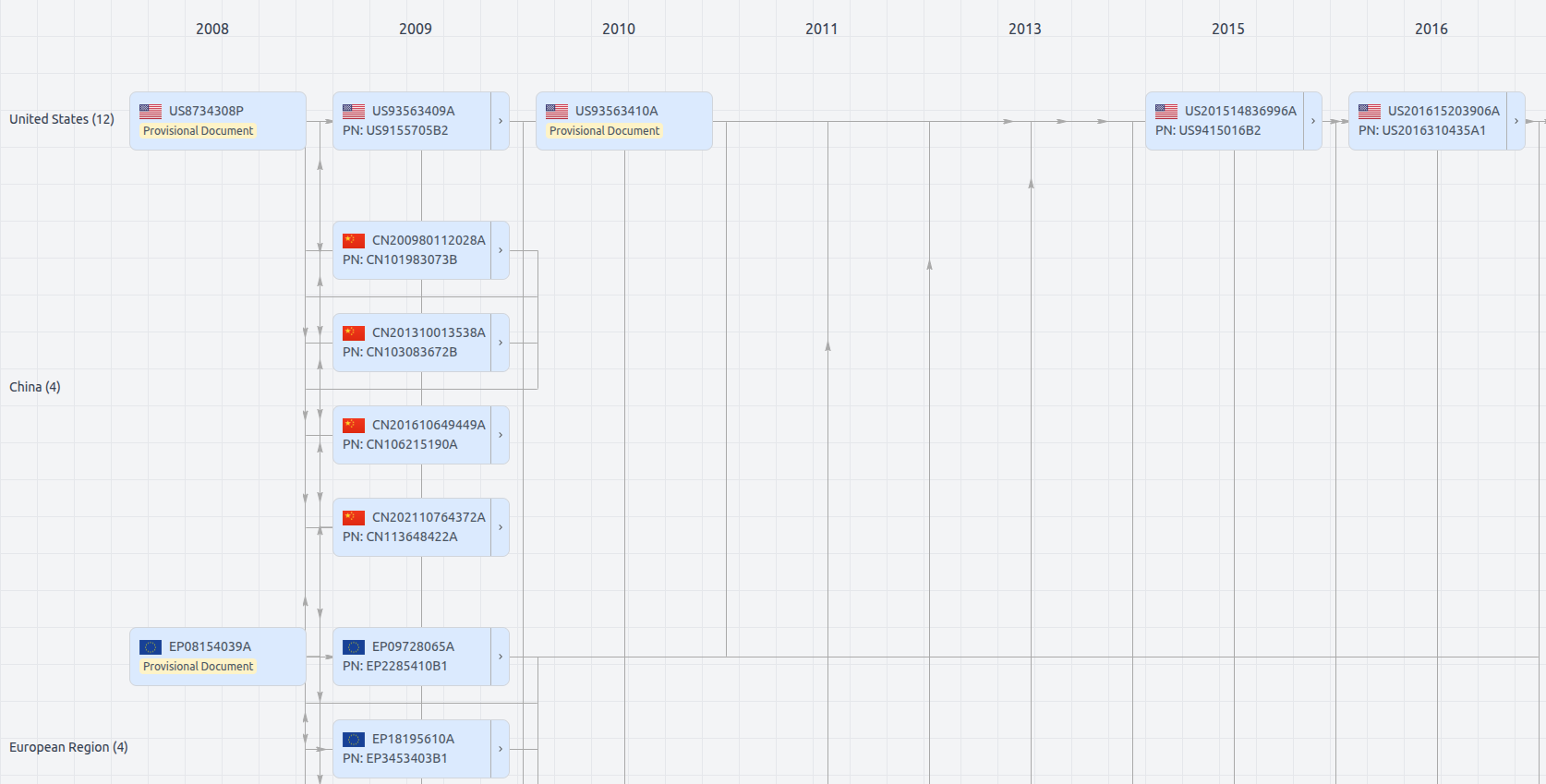

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US11732709

- Application Number

- US17532060

- Filing Date

- Nov 22, 2021

- Status

- Granted

- Expiry Date

- Mar 13, 2038

- External Links

- Slate, USPTO, Google Patents