Remediation Of Toxins In Biorefinery Process Streams

Patent No. US11882861 (titled "Remediation Of Toxins In Biorefinery Process Streams") was filed by Jpmorgan Chase Bank Na on Jul 15, 2021.

What is this patent about?

’861 is related to the field of biorefineries, specifically addressing the problem of mycotoxin contamination in feedstock used for producing ethanol and other co-products like animal feed. Cereal grains, a common feedstock, are often susceptible to fungal infections that produce harmful mycotoxins, such as deoxynivalenol (DON). These toxins can negatively impact the quality and value of the co-products, necessitating a remediation strategy.

The underlying idea behind ’861 is to introduce a toxin mitigant into the biorefinery process stream to react with and neutralize the mycotoxins present. This involves adding a treatment compound, such as a sulfur-containing compound, to one or more process streams at various stages of the biorefinery operation. The treatment compound reacts with the mycotoxin, converting it into a less toxic or non-toxic derivative, thereby improving the quality of the final products.

The claims of ’861 focus on a grain biorefinery that includes a fermentation system, a distillation system, a separation system, a thin stillage processing system, and a remediation system. The remediation system comprises a reactant storage system containing one or more treatment compounds that react with deoxynivalenol (DON). The remediation system is configured to add an adjustable amount of the treatment compounds into the thin stillage stream and/or one or more biorefinery process streams to reduce toxicity.

In practice, the treatment compound, such as sodium bisulfite, is introduced into the thin stillage or syrup stream, where the mycotoxins are concentrated. The reaction is facilitated by the aqueous environment and elevated temperatures present in these streams. The amount of treatment compound added is adjustable based on the level of mycotoxins present, ensuring optimal remediation without excessive use of chemicals. The resulting product has a significantly reduced concentration of harmful mycotoxins.

This approach differs from prior solutions by directly addressing the mycotoxin contamination within the biorefinery process itself, rather than relying solely on pre-treatment of the feedstock. By targeting the thin stillage or syrup stream, the invention leverages the concentration of toxins in these streams to achieve efficient remediation. The use of sulfur-containing compounds to form less toxic sulfonated derivatives of mycotoxins is a key aspect of the chemical transformation that distinguishes this invention.

How does this patent fit in bigger picture?

Technical landscape at the time

In the late 2010s when ’861 was filed, biorefineries at a time when biorefineries commonly relied on cereal grains as feedstock for the production of target chemicals. At that time, these grains were typically milled and processed to convert starch and/or cellulose into fermentable sugars, which were then fermented by microorganisms. The resulting fermentation product was then separated into the target chemical and co-products, with nutritional co-products being particularly valuable.

Novelty and Inventive Step

The examiner approved the application because other available prior art does not teach or suggest, either individually or in combination, the limitations of claim 1, which requires a grain biorefinery. The closest prior art, Lowe et al., discloses a method of reducing mycotoxin contamination in distillers' co-products, but it does not teach or suggest the biorefinery system as claimed.

Claims

This patent contains 29 claims, with claim 1 being independent. The independent claim focuses on a grain biorefinery that includes a remediation system for reducing mycotoxins. The dependent claims generally elaborate on specific features, configurations, and methods related to the biorefinery and the remediation system.

Key Claim Terms New

Definitions of key terms used in the patent claims.

Litigation Cases New

US Latest litigation cases involving this patent.

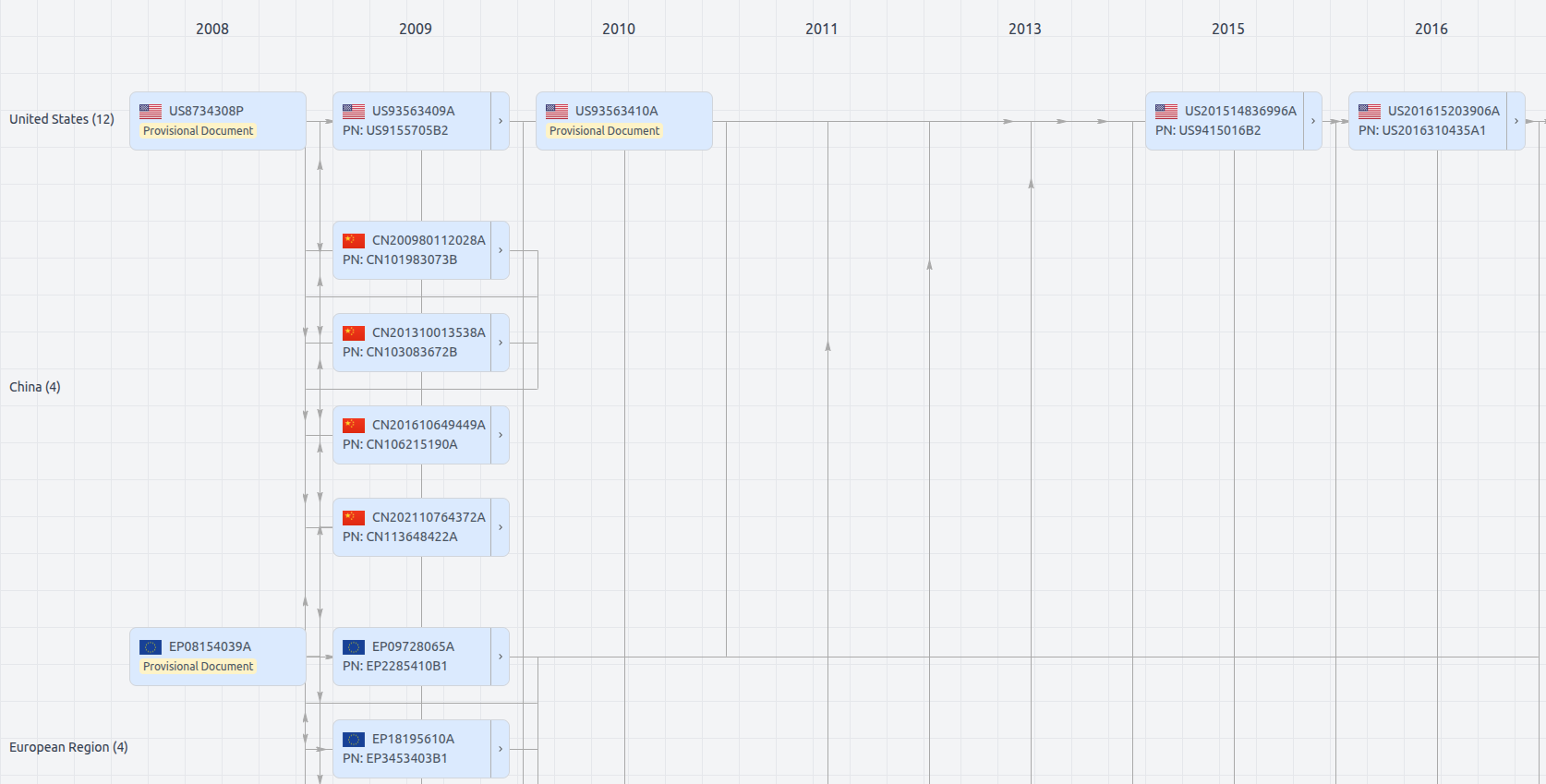

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US11882861

- Application Number

- US17377130

- Filing Date

- Jul 15, 2021

- Status

- Granted

- Expiry Date

- Aug 7, 2039

- External Links

- Slate, USPTO, Google Patents