Optoelectronic Semiconductor Component And Method Of Producing An Optoelectronic Semiconductor Component

Patent No. US11949052 (titled "Optoelectronic Semiconductor Component And Method Of Producing An Optoelectronic Semiconductor Component") was filed by Ams-Osram International Gmbh on Feb 7, 2019.

What is this patent about?

’052 is related to the field of optoelectronic semiconductor components, specifically light-emitting diodes (LEDs). The background involves efficiently extracting light from the active region of a semiconductor device while ensuring reliable electrical contact. A key challenge is minimizing light absorption by the contact metallization while maintaining good electrical conductivity and long-term stability, especially under harsh environmental conditions.

The underlying idea behind ’052 is to create a bottom-side contact for an LED that minimizes optical losses and maximizes electrical contact area. This is achieved by using an electrically insulating separation layer with multiple small, frustoconical openings. These openings expose the semiconductor material, allowing a continuous metallization layer to directly contact the semiconductor. An adhesion-promoting layer ensures good adhesion between the separation layer and the metallization.

The claims of ’052 focus on an optoelectronic semiconductor component comprising a semiconductor layer sequence with an active zone for generating radiation, an electrically insulating separation layer with a plurality of openings positioned against the bottom side of the semiconductor layer sequence, an adhesion-promoting layer next to the openings on a side of the separation layer facing away from the semiconductor layer sequence, and a continuous metallization layer on a side of the adhesion-promoting layer facing away from the semiconductor layer sequence. The semiconductor layer sequence is in direct electrical contact with the continuous metallization layer within the openings, which are frustoconical in shape and spaced from the active zone.

In practice, the device is fabricated by first growing the semiconductor layer sequence. Then, the insulating separation layer and adhesion-promoting layer are deposited. Openings are created using photolithography and etching. The metallization layer is then applied, making direct contact with the semiconductor in the openings. The frustoconical shape of the openings facilitates good metal coverage and electrical contact. A barrier layer and coupling layer can be added for improved reliability and connection to external circuitry.

This design differentiates itself from prior approaches by using a continuous metallization layer that directly contacts the semiconductor through multiple small openings, rather than a single large contact. The insulating separation layer ensures that the metallization is spaced away from the active region, minimizing light absorption. The adhesion-promoting layer and barrier layer enhance the mechanical and electrical stability of the contact, preventing degradation and ensuring long-term performance, even in the presence of humidity, corrosive gases, or electrical fields.

How does this patent fit in bigger picture?

Technical landscape at the time

In the late 2010s when ’052 was filed, optoelectronic semiconductor components, such as LED chips, were at a time when efficient electrical contacting and light extraction were key design considerations. At that time, it was common to use metallization layers for electrical contact, but optical losses due to absorption in the contact area were a concern. Systems commonly relied on dielectric separation layers to provide electrical insulation, but achieving good adhesion between these layers and the semiconductor material was non-trivial. When hardware or software constraints made precise control of layer morphology and material properties essential for achieving high performance and long-term stability.

Novelty and Inventive Step

The examiner allowed the claims because no prior art, whether taken individually or in combination, taught or suggested a continuous metallization layer positioned on the side of an adhesion-promoting layer facing away from the semiconductor layer sequence. The semiconductor layer sequence is in direct electrical contact with the continuous metallization layer within the plurality of openings of the electrically insulating separation layer. The plurality of openings are spaced apart from one another, such that the electrically insulating separation layer adjoins the bottom side of the semiconductor layer sequence at any position laterally beside the plurality of openings. The electrically insulating separation layer and the adhesion-promoting layer are arranged in between directly adjacent openings. The plurality of openings in the electrically insulating separation layer do not overlap with the electrode in the semiconductor layer sequence in a top view of the optoelectronic semiconductor component. Claims depending on this independent claim were also deemed allowable.

Claims

This patent contains 14 claims, with claim 1 being the only independent claim. Independent claim 1 is directed to an optoelectronic semiconductor component with a specific arrangement of semiconductor layers, an insulating separation layer with openings, an adhesion-promoting layer, and a continuous metallization layer. The dependent claims generally elaborate on and refine the features of the optoelectronic semiconductor component described in the independent claim, adding details regarding materials, layers, and dimensions.

Key Claim Terms New

Definitions of key terms used in the patent claims.

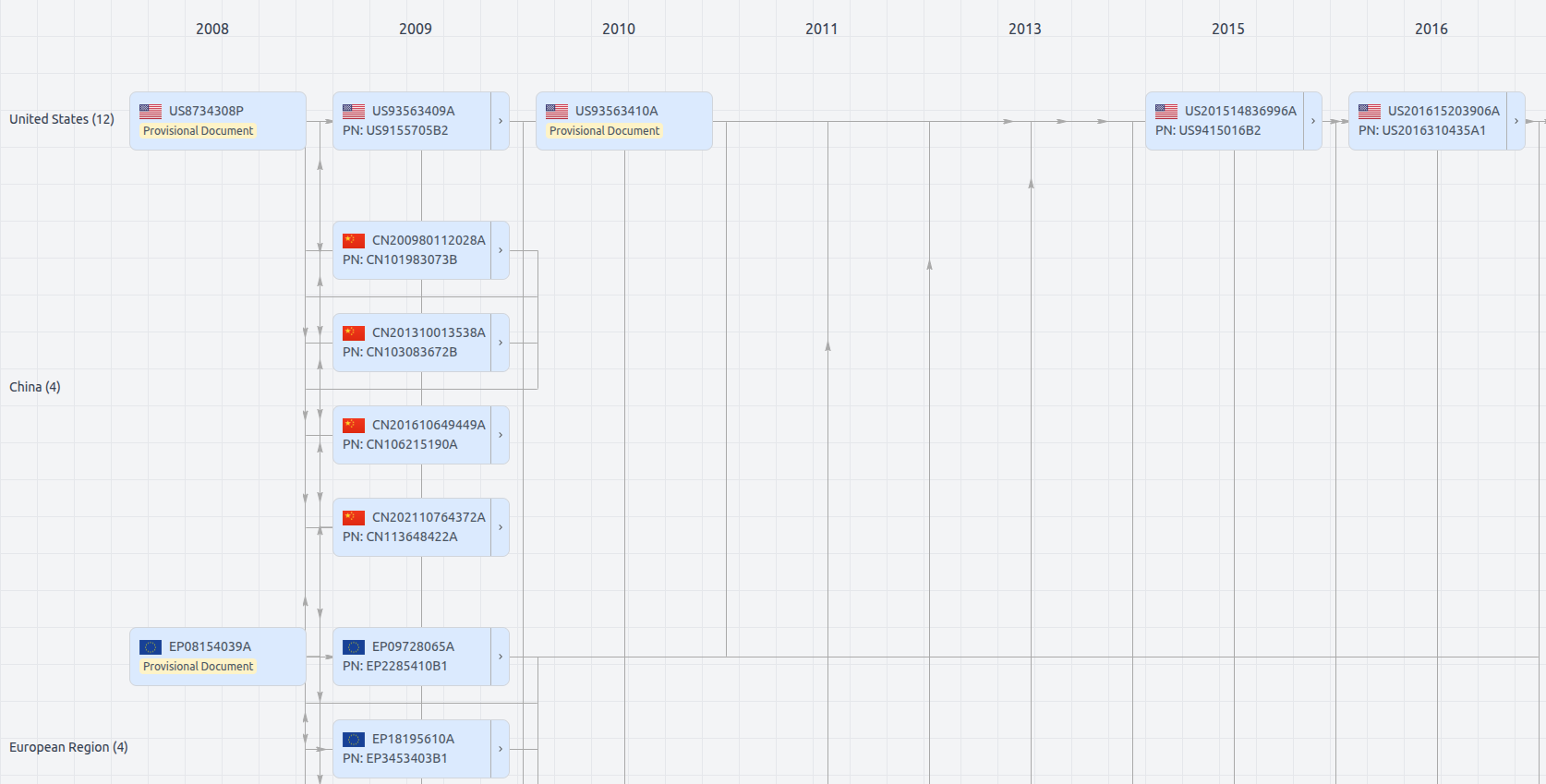

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US11949052

- Application Number

- US16969855

- Filing Date

- Feb 7, 2019

- Status

- Granted

- Expiry Date

- Jun 25, 2039

- External Links

- Slate, USPTO, Google Patents