Multiplexed Thermal Control Wafer And Coldplate

Patent No. US12000885 (titled "Multiplexed Thermal Control Wafer And Coldplate") was filed by Aem Singapore Pte Ltd on Dec 20, 2023.

What is this patent about?

’885 is related to the field of thermal management for semiconductor wafer testing, specifically addressing the need for precise and rapid temperature control during wafer probe testing. Traditional thermal control systems often struggle to respond to localized temperature variations caused by high-performance integrated circuit (IC) chips under test, leading to testing inefficiencies and potential damage to the device under test (DUT). The patent aims to improve upon these limitations by providing a system capable of quickly and accurately adjusting the temperature of individual chips or zones on a wafer.

The underlying idea behind ’885 is to use a thermal control assembly (TCA) with independently controllable thermal zones , each capable of heating or cooling a specific area of a semiconductor wafer. This allows for targeted temperature adjustments based on the power dissipation and thermal characteristics of individual DUTs. By selectively applying energy to these zones, the system can achieve higher power densities and faster temperature transitions compared to traditional, less granular thermal control methods.

The claims of ’885 focus on a thermal control assembly (TCA) that includes a plurality of independently controllable thermal zones. These zones comprise both independently controllable heater zones and independently controllable cooling zones. The key aspect is that energy input to the TCA is selectively applied to one or more of the heater zones , enabling localized temperature control of the top surface of the TCA.

In practice, the TCA would be positioned beneath a semiconductor wafer during probe testing. The thermal controller receives information about the location and power consumption of the DUTs on the wafer. Based on this information, the controller selectively activates the appropriate heater and/or cooling zones to maintain the desired temperature for each DUT. This selective activation allows for a higher power density in the active zones, enabling faster temperature changes and more precise control.

The invention differentiates itself from prior approaches by offering a more granular and responsive thermal control system. Instead of applying uniform heating or cooling to the entire wafer, ’885 allows for targeted temperature adjustments based on the specific needs of each DUT. This is achieved through the use of independently controllable thermal zones and a control system that can selectively activate these zones based on real-time information about the DUTs. This approach leads to improved testing efficiency, reduced risk of damage to the DUTs, and more accurate characterization of their performance.

How does this patent fit in bigger picture?

Technical landscape at the time

In the early 2020s when ’885 was filed, thermal control of IC wafers during probe testing was typically implemented using thermal masses with relatively large thermal inertia. At a time when systems commonly relied on single-zone heating or cooling, localized temperature control of individual chips on a wafer was non-trivial. When hardware or software constraints made rapid temperature transitions challenging, testing throughput was limited.

Novelty and Inventive Step

The examiner approved the patent because independent claim 1 recites a probing apparatus with "a plurality of independently controllable heater zones and a plurality of independently controllable cooling zones configured to maintain or change a temperature of a top surface of the TCA," which the cited prior art does not anticipate or render obvious.

Claims

This patent contains 29 claims, with claim 1 being independent. Independent claim 1 is directed to a thermal control assembly with independently controllable thermal zones. The dependent claims elaborate on specific configurations, components, and functionalities of the thermal control assembly, such as the energy input method, the type of component being temperature controlled, the size and arrangement of the thermal zones, and the structure of a thermal control wafer.

Key Claim Terms New

Definitions of key terms used in the patent claims.

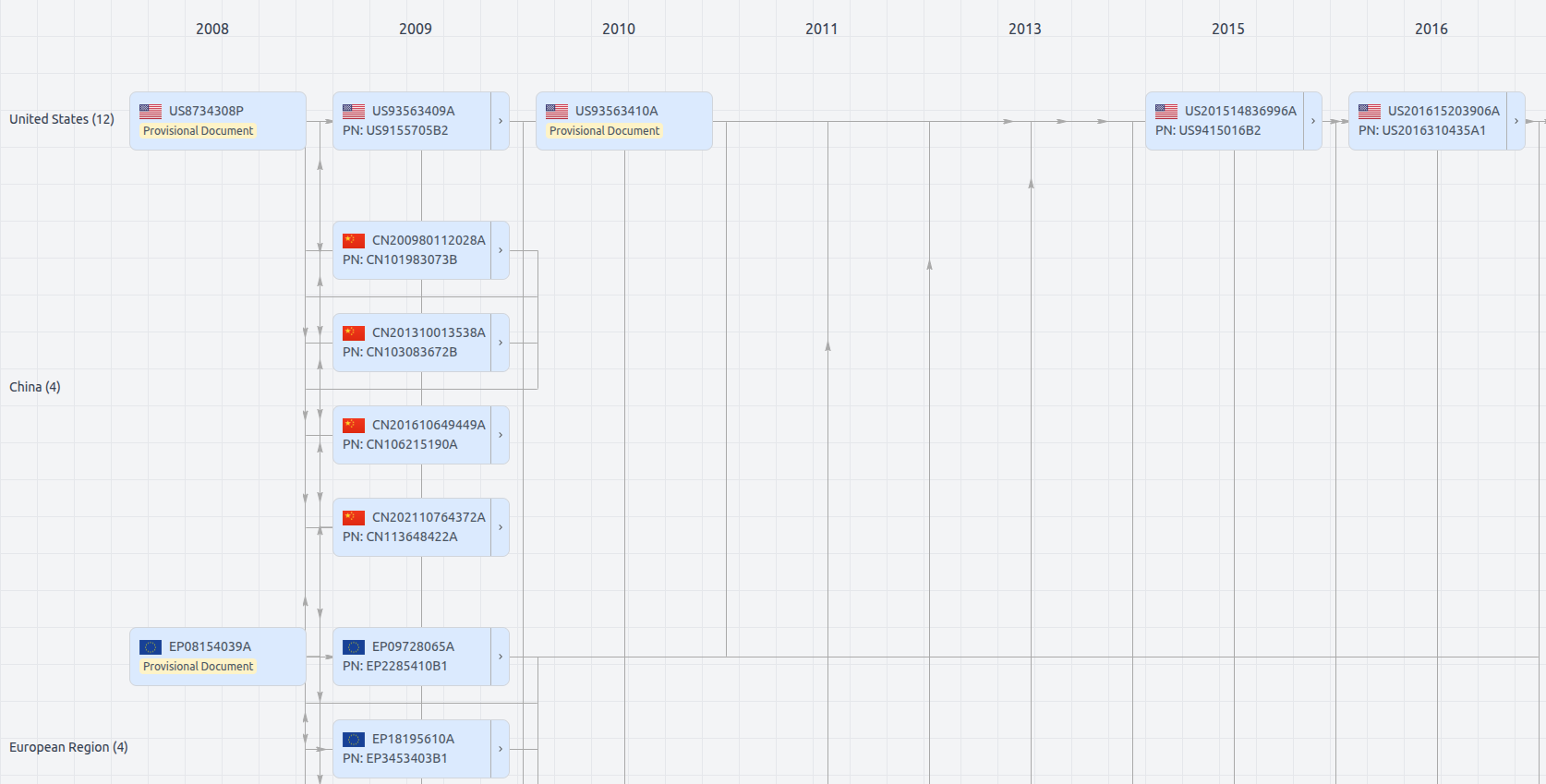

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US12000885

- Application Number

- US18390918

- Filing Date

- Dec 20, 2023

- Status

- Granted

- Expiry Date

- Dec 20, 2043

- External Links

- Slate, USPTO, Google Patents