Main Shaft Fixture

Patent No. US12104578 (titled "Main Shaft Fixture") was filed by Liftra Ip Aps on Jan 24, 2024.

What is this patent about?

’578 is related to the field of wind turbine maintenance, specifically addressing the challenge of safely and efficiently servicing heavy components within the nacelle. Traditional methods of fixing the main shaft during these operations often require halting turbine operation and using inflexible fixtures, leading to energy production losses and logistical difficulties due to varying shaft geometries. The patent aims to overcome these limitations.

The underlying idea behind ’578 is to provide a modular main shaft fixture that can be installed on existing nacelle structures without stopping the turbine. This fixture uses adjustable pressure mandrels with tap shoes to accommodate different shaft geometries. Furthermore, the fixture incorporates mounting points for both lightweight and self-hoisting cranes, streamlining the process of lifting and replacing heavy components.

The claims of ’578 focus on a main shaft fixture designed for wind turbine maintenance. The fixture is characterized by adjustable pressure mandrels with tap shoes that can be moved between a retracted position (away from the shaft) and an engaged position (contacting the shaft). Crucially, the fixture also includes mounting facilities for anchoring a crane within the nacelle.

In practice, the fixture is assembled in sections onto the nacelle's bottom frame. The adjustable mandrels are then extended to contact and secure the main shaft, providing stability for maintenance work. The integrated crane mounting points allow for efficient hoisting of tools and components, reducing the need for large external cranes and minimizing downtime. The adjustability of the mandrels allows the same fixture to be used on different turbine models.

The key differentiation from prior solutions lies in the combination of adaptability and integration. The adjustable mandrels eliminate the need for custom fixtures for each shaft geometry. The integrated crane mounting points streamline the maintenance process, reducing setup time and reliance on external equipment. Some embodiments also include a rotor lock and actuators to allow for controlled vertical displacement of the main shaft, facilitating bearing replacement without complete disassembly.

How does this patent fit in bigger picture?

Technical landscape at the time

In the mid-2010s when ’578 was filed, wind turbine maintenance at a time when fixing the main shaft during repairs was typically implemented using external fixtures. These fixtures were mounted after halting the turbine and locking the rotor, which caused downtime and energy production losses. Furthermore, the fixtures were often inflexible, requiring different fixtures for different shaft geometries. The increasing use of self-hoisting cranes with ground-based winches also created a need for anchoring facilities in the nacelle.

Novelty and Inventive Step

The examiner approved the application because the prior art does not teach a main shaft fixture that also includes mounting facilities adapted for anchoring a crane on or in a wind turbine nacelle.

Claims

This patent includes 17 claims, with independent claims numbered 1, 15, and 16. The independent claims generally focus on a main shaft fixture used for fixing a wind turbine's main shaft during installation and repair, incorporating adjustable pressure mandrels and crane mounting facilities. The dependent claims elaborate on specific features and variations of the main shaft fixture described in the independent claims.

Key Claim Terms New

Definitions of key terms used in the patent claims.

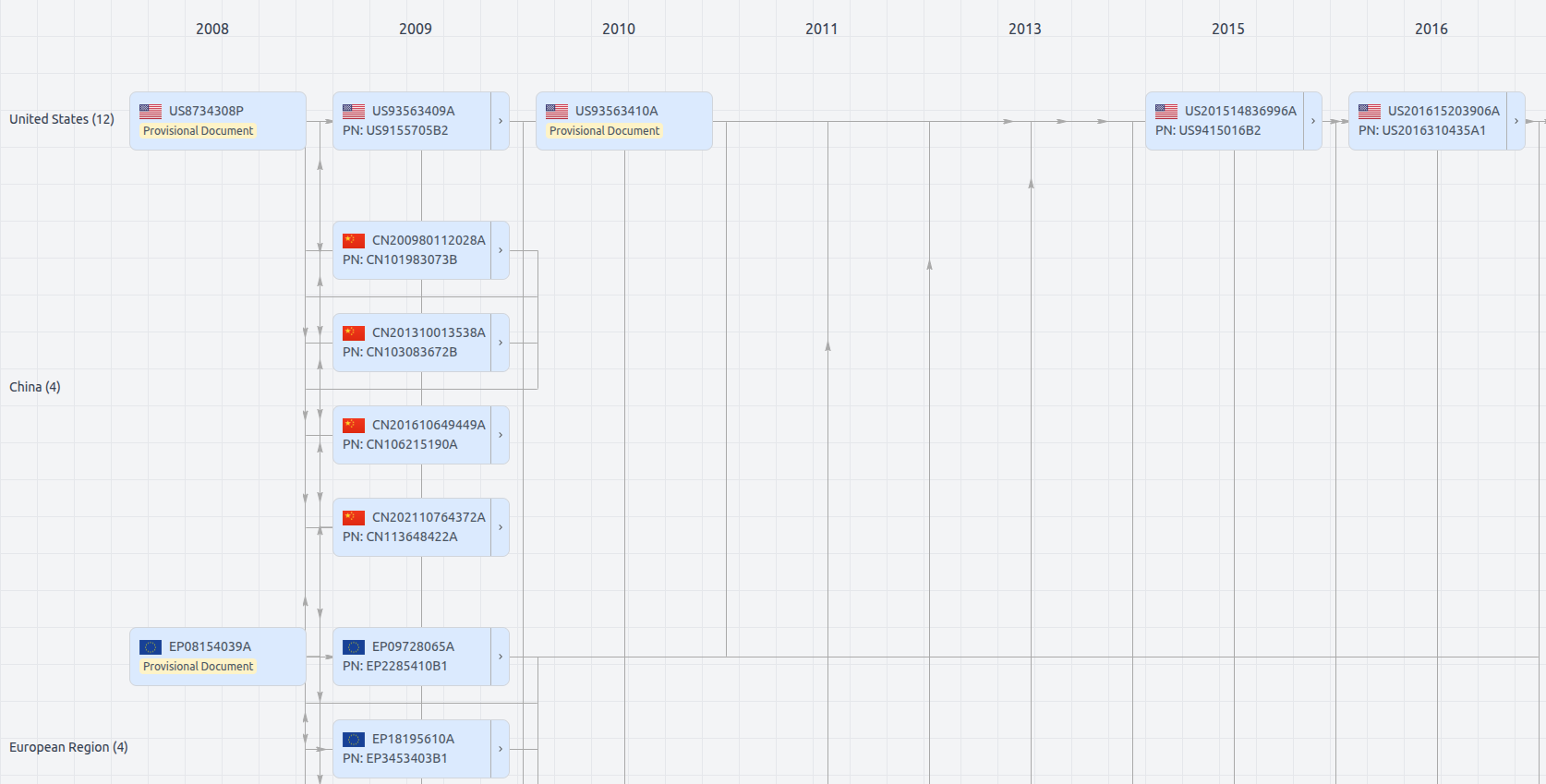

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US12104578

- Application Number

- US18420859

- Filing Date

- Jan 24, 2024

- Status

- Granted

- Expiry Date

- Oct 6, 2035

- External Links

- Slate, USPTO, Google Patents