Visible Laser Welding Of Electronic Packaging, Automotive Electrics, Battery And Other Components

Patent No. US12220764 (titled "Visible Laser Welding Of Electronic Packaging, Automotive Electrics, Battery And Other Components") was filed by Blue 425 Llc on Apr 28, 2017.

What is this patent about?

’764 is related to the field of laser material processing, specifically laser welding. The patent addresses the challenges of welding highly reflective metals like copper, aluminum, and stainless steel, which are commonly used in battery packs and other energy storage devices. Traditional infrared lasers struggle with these materials due to their low absorptivity at infrared wavelengths, leading to inconsistent welds and narrow processing windows.

The underlying idea behind ’764 is to use a blue laser (wavelengths between 400 nm and 500 nm) for welding these metals. The key inventive insight is that these materials exhibit significantly higher absorptivity in the blue light spectrum compared to the infrared spectrum. This higher absorptivity allows for more efficient energy coupling, resulting in more consistent, controllable, and repeatable welds with lower power requirements.

The claims of ’764 focus on a method for joining two metal components using a blue laser beam. The method involves directing the blue laser beam, with a wavelength between 400 nm and 500 nm, onto the target location where the two components meet. The claims specify that at least one of the components must have an absorptivity of at least 45% at the laser's wavelength, and that at least 45% of the laser beam's energy must be utilized to form the weld. The resulting weld is characterized by a low resistivity (0.1 mΩ to 250 mΩ).

In practice, the blue laser system delivers a focused beam onto the joint between the two metal components. A scanning device moves the beam in a predetermined pattern to create the weld. Because of the higher absorptivity, the laser intensity can remain relatively constant throughout the welding process, avoiding the runaway effects often seen with infrared lasers. The system can be used to weld various combinations of metals, including copper, aluminum, nickel-plated materials, and stainless steel, in configurations such as foil-to-foil, foil-to-tab, and tab-to-buss bar.

This approach differs significantly from prior art infrared laser welding. The use of a blue laser allows for welding with lower power and greater control , leading to more reproducible and reliable welds. The higher absorptivity also reduces the risk of overheating and material damage. The patent highlights the suitability of this method for manufacturing battery packs and other electronic components where precise and consistent welds are crucial for performance and longevity.

How does this patent fit in bigger picture?

Technical landscape at the time

In the mid-2010s when ’764 was filed, laser processing of materials was at a time when conventional lasers in the IR wavelengths were typically unable to weld or to provide a consistent high quality weld of materials such as copper, aluminum, stainless steel, and nickel plated materials because of the low absorptivity of the material in those wavelengths. At this time, either a very high power laser was needed to start the process, or a very high brightness laser was needed to conduct the process, sometimes both lasers were required.

Novelty and Inventive Step

The claims were rejected under 35 U.S.C. 112(a) or 35 U.S.C. 112 (pre-AIA), first paragraph, as failing to comply with the written description requirement. The claims were also rejected under 35 U.S.C. 103 as being unpatentable over cited references. Applicant arguments were considered but were not persuasive. This action was made final. The prosecution record does NOT describe the technical reasoning or specific claim changes that led to allowance.

Claims

This patent contains 24 claims, with independent claims 1 and 17 directed to methods of joining two metal components using a blue laser beam. The independent claims generally focus on controlling laser intensity and energy to form a weld with specific resistivity characteristics. The dependent claims generally refine the parameters and conditions of the welding method described in the independent claims.

Key Claim Terms New

Definitions of key terms used in the patent claims.

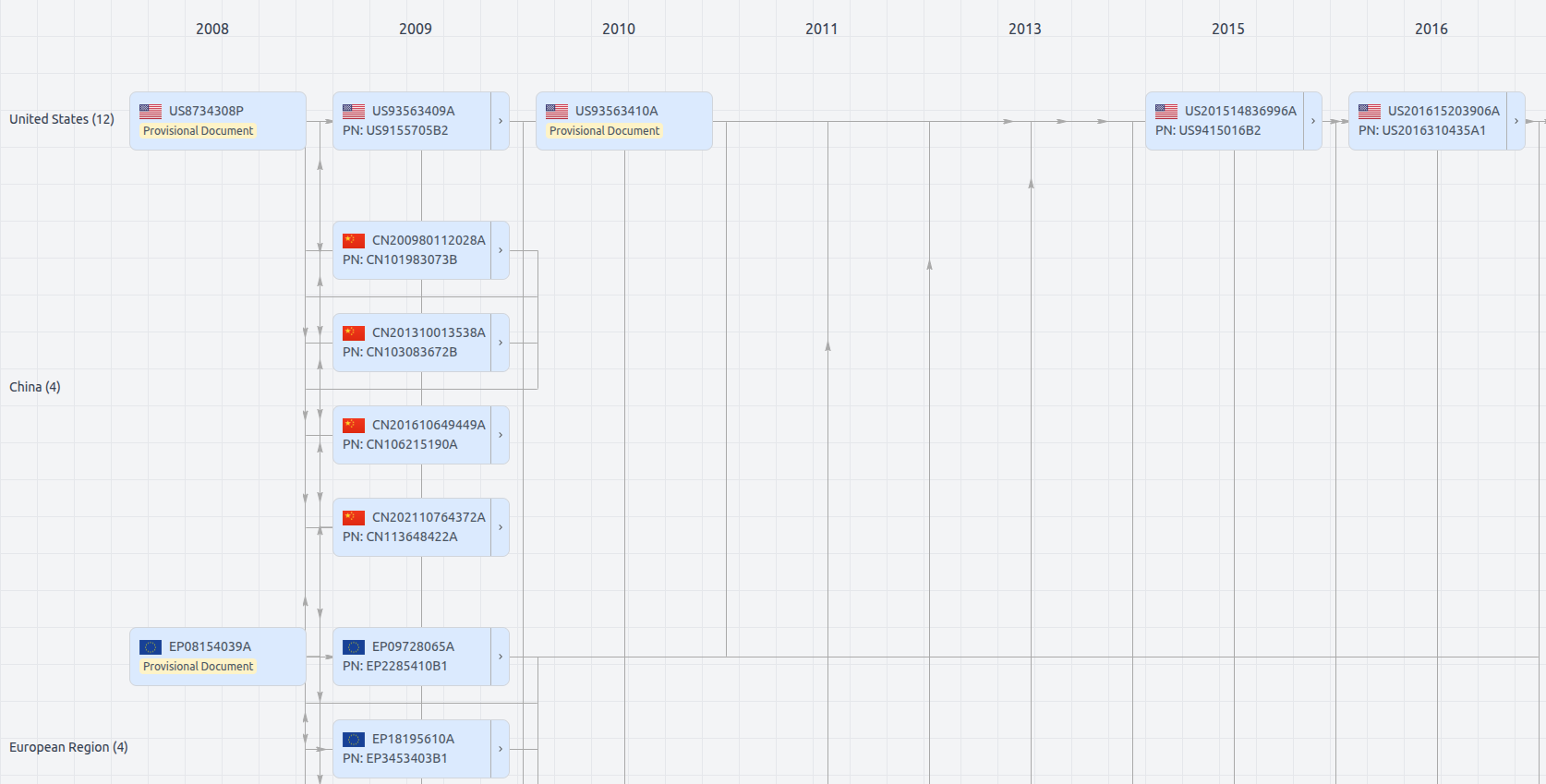

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US12220764

- Application Number

- US15581928

- Filing Date

- Apr 28, 2017

- Status

- Granted

- Expiry Date

- Apr 28, 2037

- External Links

- Slate, USPTO, Google Patents