Freeze Dryers And Drying Processes For Materials With Low Water Content

Patent No. US12245610 (titled "Freeze Dryers And Drying Processes For Materials With Low Water Content") was filed by Harvest Right Llc on Nov 18, 2024.

What is this patent about?

’610 is related to the field of freeze-drying , specifically addressing the challenge of drying materials with low water content, such as candies and confections. Traditional freeze-drying processes involve freezing the material before applying a vacuum to sublimate the ice. However, this pre-freezing step may not be necessary or even desirable for materials already low in moisture, potentially leading to inefficiencies and suboptimal results.

The underlying idea behind ’610 is to eliminate the pre-freezing step in the freeze-drying process for materials with low water content (less than 20% water). Instead of freezing, the material is placed directly into the vacuum chamber, and the pressure is reduced to initiate drying. This approach leverages the fact that low-moisture materials are structurally robust enough to withstand the vacuum without prior freezing, streamlining the process and potentially improving the final product.

The claims of ’610 focus on a freeze dryer apparatus and method specifically adapted for drying materials without a pre-freezing step. The apparatus includes a vacuum chamber, a vacuum pump, a cooling system for the chamber walls, a heating system for the material, and an electronic controller. The controller is programmed to execute a drying process that involves reducing the pressure in the chamber below ambient pressure to dry the material, skipping the initial freezing phase.

In practice, the invention operates by first cooling the interior walls of the vacuum chamber to facilitate the condensation of water vapor. The material, such as candy, is then placed inside the chamber. The electronic controller then activates the vacuum pump to reduce the pressure, initiating the drying process. In some embodiments, the material is also heated to further accelerate the removal of moisture. The controller may also offer an option to repeat the drying process with another batch of material without defrosting the chamber, further enhancing efficiency.

This approach differentiates itself from traditional freeze-drying by optimizing the process for low-moisture materials . By skipping the freezing step, the invention reduces energy consumption and processing time. Furthermore, the option to heat the material before or during drying can enhance the texture and other characteristics of the final product, particularly in the case of candies, where a desirable puffed or expanded structure is often sought. The ability to run multiple batches without defrosting also improves throughput.

How does this patent fit in bigger picture?

Technical landscape at the time

In the mid 2020s when ’610 was filed, at a time when freeze drying systems commonly relied on programmable logic controllers to manage temperature, pressure, and cycle times, hardware or software constraints made precise control and optimization of drying parameters non-trivial.

Novelty and Inventive Step

Claims 1-37 were pending in the application. The examiner issued a final rejection under 35 U.S.C. 112(b) for indefiniteness. The examiner suggested amending claim 1. Claims 1-37 were then deemed allowable because the claimed freeze dryer and method thereof with all the independently claimed features and including reducing pressure in a chamber below ambient pressure to dry material without the material being frozen was not found in the prior art either singly or in combination.

Claims

This patent contains 37 claims, with independent claims 1, 9, 18, and 26. The independent claims focus on a freeze dryer and methods of using it to dry materials, specifically candy, without freezing. The dependent claims generally elaborate on the features, settings, and steps of the freeze dryer and drying methods described in the independent claims.

Key Claim Terms New

Definitions of key terms used in the patent claims.

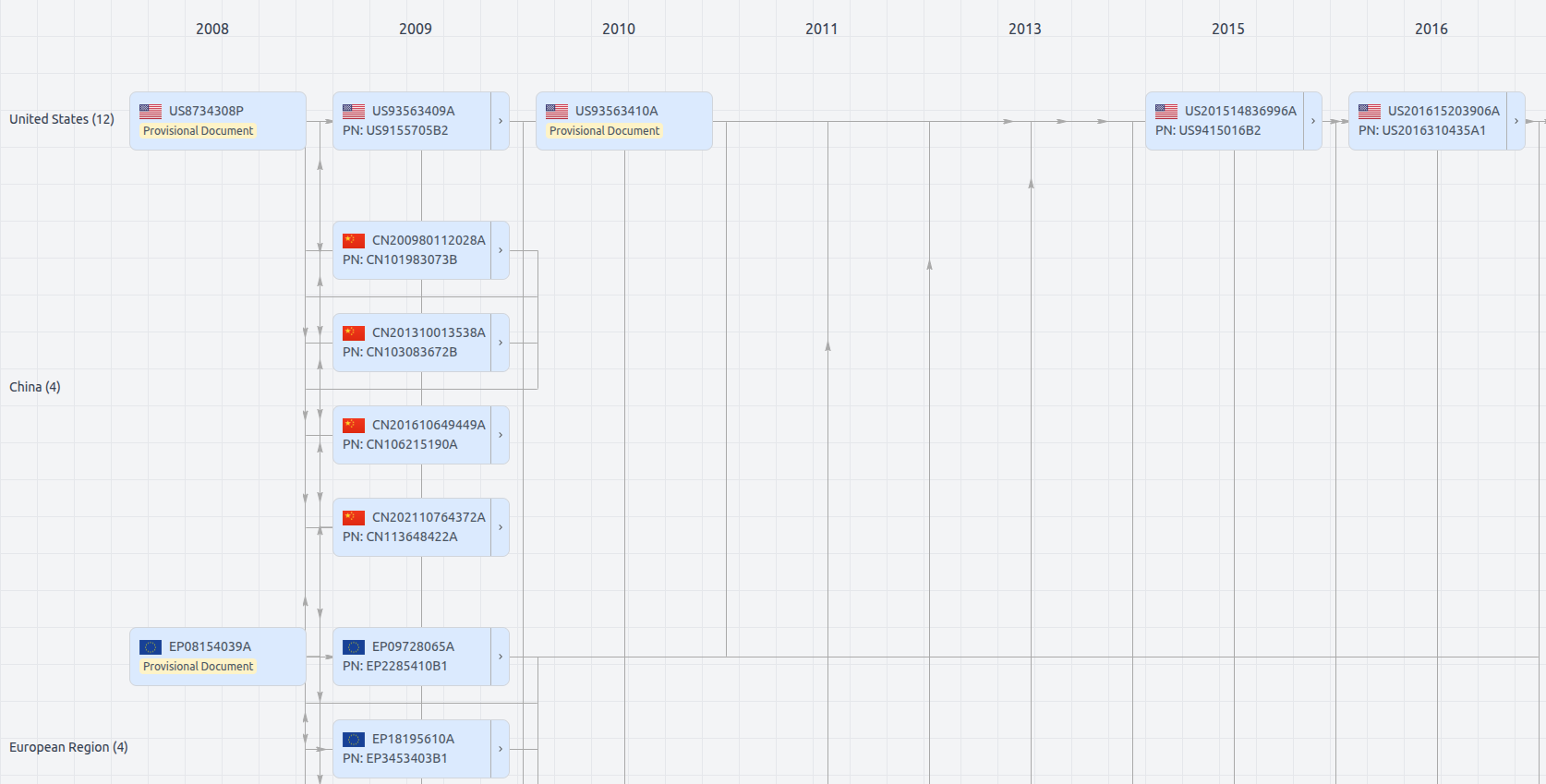

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US12245610

- Application Number

- US18951613

- Filing Date

- Nov 18, 2024

- Status

- Granted

- Expiry Date

- May 8, 2044

- External Links

- Slate, USPTO, Google Patents