Mixing Vessel Baffles For A Drink Maker

Patent No. US12279629 (titled "Mixing Vessel Baffles For A Drink Maker") was filed by Sharkninja Operating Llc on Jan 26, 2024.

What is this patent about?

’629 is related to the field of frozen drink makers, specifically addressing the problem of controlling slush flow within the mixing vessel. Existing frozen drink makers, especially those designed for household use, often struggle with slush sticking to the upper sidewalls and top of the vessel, leading to inefficient mixing and product waste. The invention aims to improve slush control, particularly in smaller units where headspace is limited.

The underlying idea behind ’629 is to strategically place internal baffles within the mixing vessel to redirect the slush flow. These baffles are designed to prevent the slush from migrating upwards and adhering to the vessel's upper surfaces. By carefully controlling the direction of the slush, the invention promotes more thorough mixing, reduces waste, and prevents the lid from being forced off due to slush buildup.

The claims of ’629 focus on a mixing vessel for a frozen drink maker that incorporates a curved sidewall defining a vessel chamber with a front, rear, right, left, and top. The key features are a corner baffle , positioned at the front top of the vessel chamber on either side, and a front baffle , positioned at the front of the vessel chamber extending across the top. These baffles are specifically configured to direct slush flow within the vessel chamber.

In practice, the baffles work by intercepting the slush as it's propelled upwards and forwards by the rotating dasher. The side baffle redirects the slush away from the upper sidewalls, while the front baffle prevents buildup at the top front of the vessel. The corner baffle , connecting the side and front baffles, ensures a smooth transition of slush flow, preventing stagnation in the corner. The positioning of the baffles is optimized based on the direction of the dasher's rotation.

This design differs from prior approaches that rely on a tall vessel chamber to provide sufficient headspace for the slush. By incorporating internal baffles, ’629 allows for a shorter chamber height, making it suitable for household frozen drink makers that need to fit under cabinets. The baffles ensure efficient slush control even with reduced headspace, preventing the issues of poor circulation, non-uniform dispensing, and product waste that plague conventional designs.

How does this patent fit in bigger picture?

Technical landscape at the time

In the early 2020s when ’629 was filed, frozen drink makers typically included a mixing vessel with a dasher to mix and cool the drink product. At a time when these systems commonly relied on a refrigeration system with a compressor, condenser, and evaporator to cool the drink product, hardware or software constraints made it non-trivial to control the slush flow within the mixing vessel to ensure thorough mixing and prevent blockage.

Novelty and Inventive Step

The examiner approved the application because the prior art does not describe the specific arrangement of baffles claimed. Specifically, the prior art fails to teach or suggest a front baffle positioned at the front of the vessel chamber extending from the left side toward the right side across the top. The examiner stated that combining references to achieve this arrangement would either destroy one reference or involve impermissible hindsight.

Claims

This patent contains 25 claims, with independent claims 1, 13, and 20. The independent claims focus on a mixing vessel with baffles for a frozen drink maker, and a frozen drink maker that includes such a mixing vessel. The dependent claims generally add specific details and features to the mixing vessel and its components, or to the frozen drink maker.

Key Claim Terms New

Definitions of key terms used in the patent claims.

Litigation Cases New

US Latest litigation cases involving this patent.

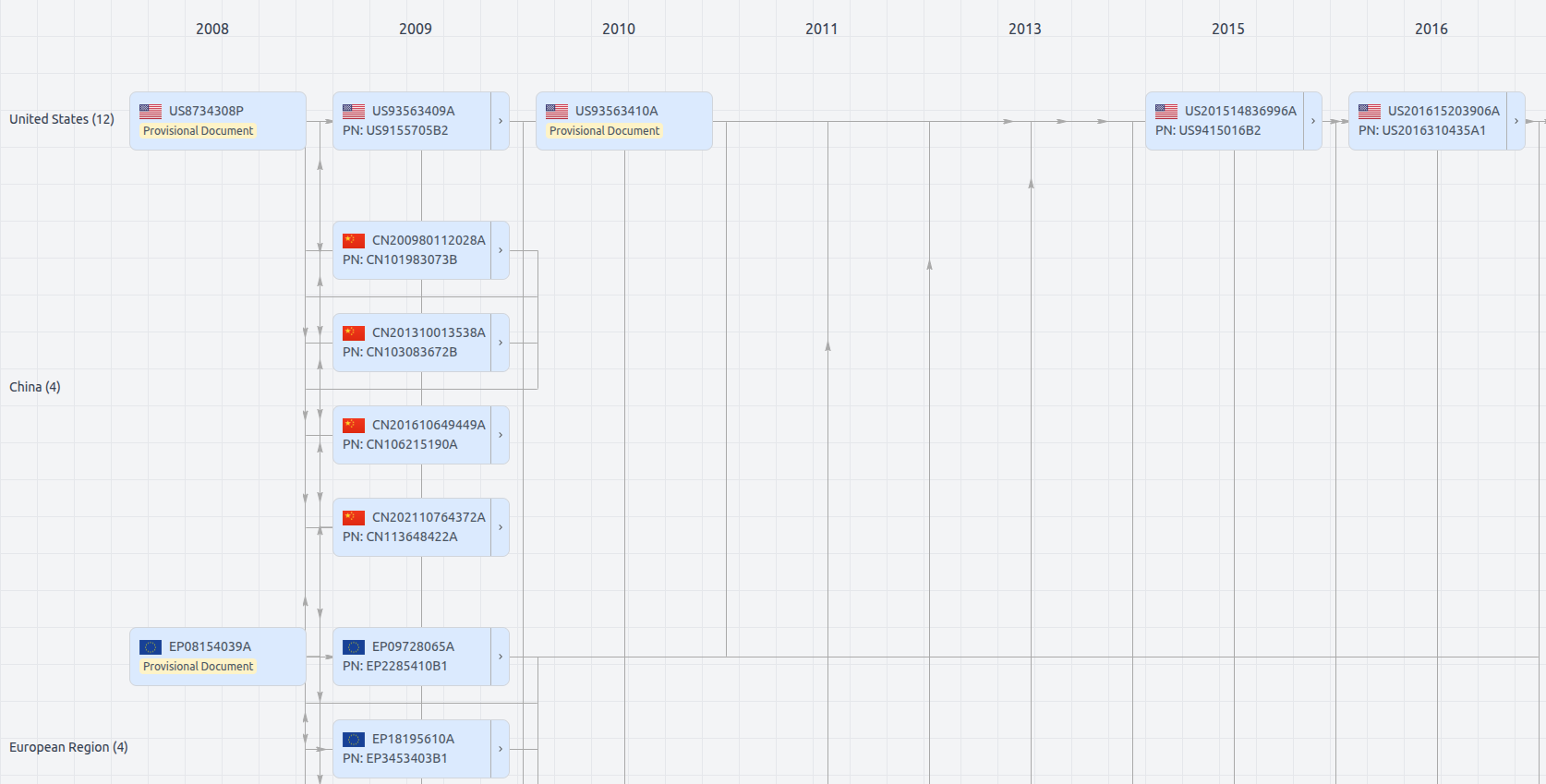

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US12279629

- Application Number

- US18423899

- Filing Date

- Jan 26, 2024

- Status

- Granted

- Expiry Date

- Jan 18, 2044

- External Links

- Slate, USPTO, Google Patents