Adjustable Hitch Assembly

Patent No. US10857846 (titled "Adjustable Hitch Assembly") was filed by Uriah Products Llc on Apr 11, 2018.

What is this patent about?

’846 is related to the field of land vehicle towing, specifically adjustable hitch assemblies that connect a tow vehicle to a trailer. These assemblies allow for adjustments in the height of the hitch ball to accommodate different trailer heights, ensuring level towing. The background involves various designs for such adjustable hitches, aiming for strength, ease of adjustment, and versatility.

The underlying idea behind ’846 is a specific mechanical arrangement for an adjustable hitch. It uses an L-shaped bracket with a vertical post (tenon) and a horizontal drawbar. A C-shaped mounting block slides vertically on the post, and this block holds one or more hitch balls. The key is the combination of the L-bracket providing the structural support and connection to the vehicle, with the sliding block enabling height adjustment and ball mounting.

The claims of ’846 focus on an adjustable hitch assembly featuring an L-shaped hitch bracket with a horizontal drawbar and a vertical tenon. A vertically-adjustable hitch-ball mounting block, having a C-shaped structure with a slotted mortise hole, receives the tenon for sliding adjustment. The mounting block includes a through hole to accommodate a hitch ball with a cylindrical shank, secured by a pin. Claim 9 specifies two hitch balls mounted head-up and head-down, secured by two pins.

In practice, the L-shaped bracket is inserted into the receiver tube of the tow vehicle and secured with a pin. The C-shaped mounting block slides up or down the vertical tenon of the L-bracket to the desired height, and is then secured in place with pins through aligned holes. The hitch ball, or balls, are then secured within the mounting block using cap screws that pass through the block and thread into the shank of the ball. This allows for quick adjustment of the hitch height to match the trailer.

The design differentiates itself by using a specific combination of an L-shaped bracket and a C-shaped mounting block. The gusset on the L-bracket adds strength, and the shallow channels on the bracket allow the mounting block to be easily removed for changing the hitch ball configuration. The use of extruded aluminum for the bracket and mounting block, combined with steel hitch balls, balances strength and weight. The long, tapered necks on the hitch balls provide ample clearance for the trailer coupler.

How does this patent fit in bigger picture?

Technical landscape at the time

In the late 2010s when ’846 was filed, ball and socket hitch apparatuses were at a time when X was typically implemented using Y. At this time, systems commonly relied on Z rather than A. Hardware or software constraints made B non-trivial.

Novelty and Inventive Step

Claims 1-6 and 20 were rejected. Claims 7-19 were objected to. The prosecution record does NOT describe the technical reasoning or specific claim changes that led to allowance.

Claims

This patent contains 16 claims, with independent claims 1 and 9 directed to an adjustable hitch assembly. The independent claims generally focus on the structural components of the hitch assembly, including the hitch bracket and vertically-adjustable hitch-ball mounting block. The dependent claims generally add further detail and limitations to the features described in the independent claims.

Key Claim Terms New

Definitions of key terms used in the patent claims.

Litigation Cases New

US Latest litigation cases involving this patent.

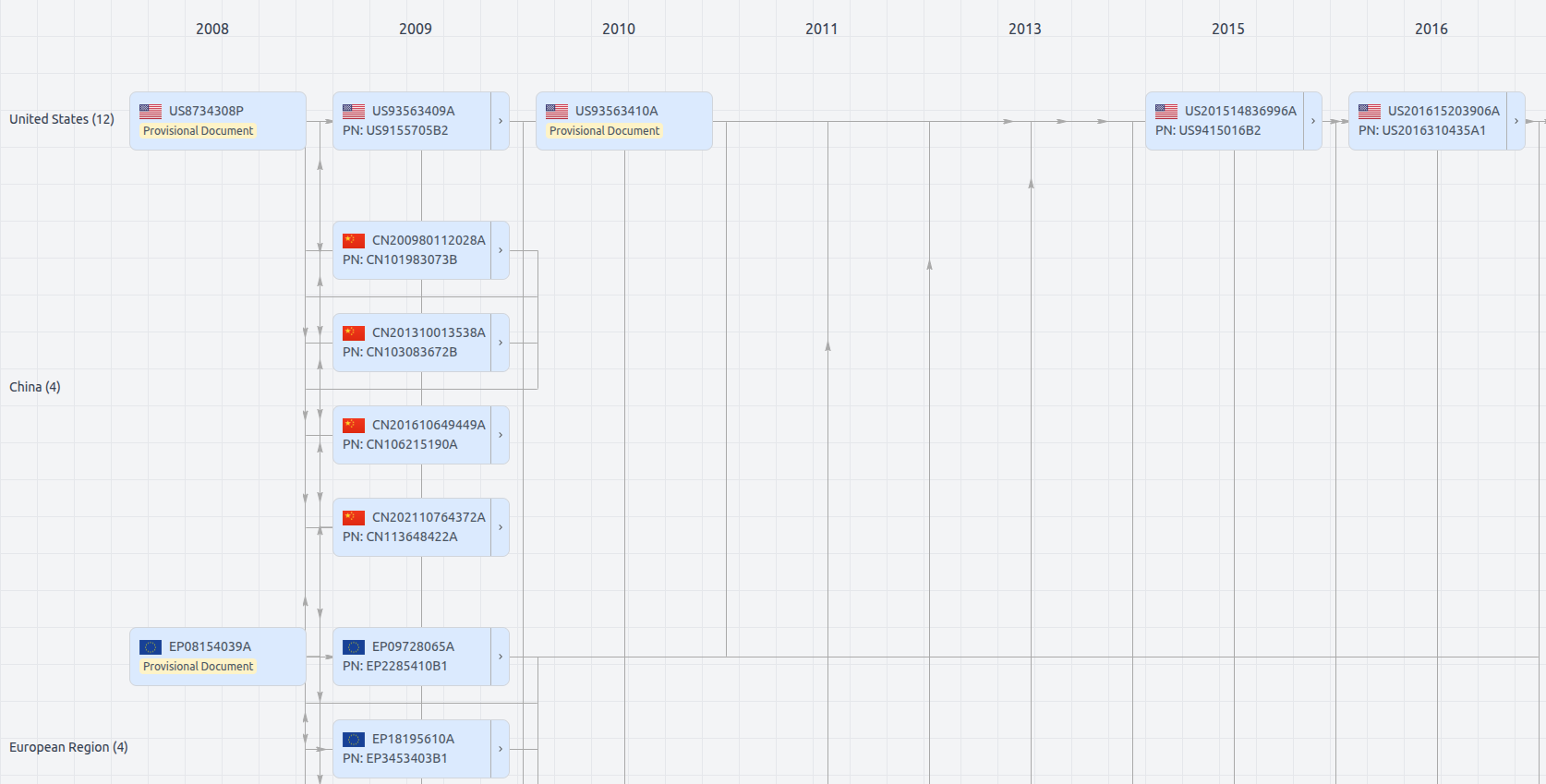

Patent Family

File Wrapper

The dossier documents provide a comprehensive record of the patent's prosecution history - including filings, correspondence, and decisions made by patent offices - and are crucial for understanding the patent's legal journey and any challenges it may have faced during examination.

Date

Description

Get instant alerts for new documents

US10857846

- Application Number

- US15950586

- Filing Date

- Apr 11, 2018

- Status

- Granted

- Expiry Date

- Dec 18, 2038

- External Links

- Slate, USPTO, Google Patents